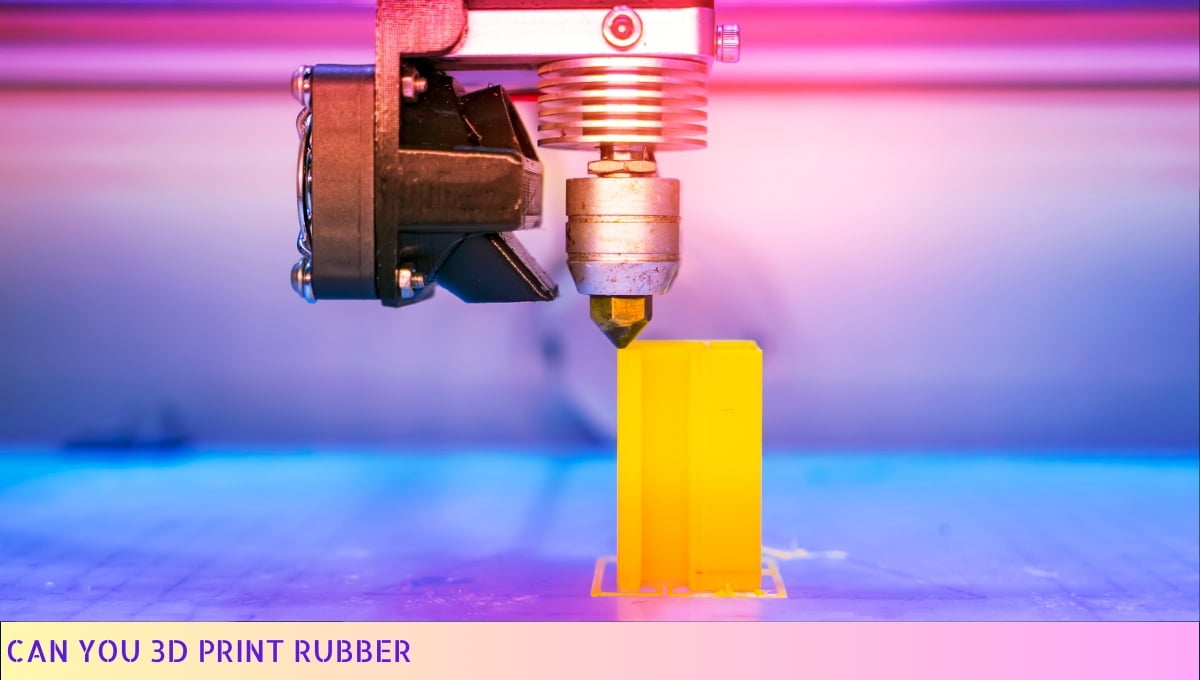

Yes, a 3D printer can print a 3D printer.

This is possible through a process called self-replication, where a 3D printer creates the necessary components and assembles them to create another 3D printer.

This concept is known as “RepRap” (short for replicating rapid prototyper) and has been successfully implemented, allowing for the creation of more 3D printers without human intervention.

It demonstrates the power and potential of additive manufacturing technology.

I. The Possibility of 3D Printers Printing Themselves

Alright folks, let’s dive into the mind-blowing world of 3D printing. And get ready for a twist that will make your jaw drop – 3D printers that can actually print themselves!

Yes, you heard me right, these marvelous machines have the potential to create their own kind. It’s like a robot giving birth to another robot. Mind. Blown.

Now, before we go any further, let me tell you why this mind-boggling concept is more than just a sci-fi dream.

It’s all about the magic of replication, my friends. When a 3D printer has the ability to produce its own components, it opens up a whole new world of possibilities.

Imagine the convenience of having a machine that can repair or upgrade itself, without you having to lift a finger. Talk about a game-changer!

So, what are the advantages of having these self-replicating wonders in our lives? Well, buckle up because I’m about to lay it all out for you.

1. Advantages of 3D Printers Printing Other 3D Printers

1. Cost Savings: With 3D printers capable of creating their own offspring, the cost of production can be significantly reduced. No need to rely on external manufacturers or suppliers. Just sit back, relax, and let the printer do its thing.

2. Increased Accessibility: By eliminating the dependency on external sources, self-printing 3D printers can make this technology more accessible to a wider range of individuals and businesses. The democratization of 3D printing, if you will.

3. Rapid Prototyping: Picture this: you have a brilliant idea for a new product, but you need a prototype ASAP. With a self-replicating 3D printer, you can quickly iterate and refine your design without wasting time or money.

It’s like having your own personal manufacturing plant right at your fingertips.

Now, hold your horses, because as with any groundbreaking technology, there are challenges and limitations that we need to address.

2. Challenges and Limitations in 3D Printing a 3D Printer

1. Quality Control: Ensuring the precision and accuracy of the printed components is crucial for the successful replication of a 3D printer.

Any flaws or inconsistencies in the process can lead to a domino effect of errors, resulting in a less-than-optimal offspring.

2. Complexity: Let’s face it, building a 3D printer is no walk in the park. It requires a deep understanding of intricate mechanisms, electronics, and software.

The self-printing process adds another layer of complexity, making it a challenge to achieve a seamless replication.

3. Resource Limitations: In order for a 3D printer to print itself, it needs access to the necessary raw materials and components. If these resources are not readily available or affordable, the self-replication process becomes impractical.

Now, let’s fast forward to the future and ponder the implications of 3D printers printing themselves.

3. The Future Implications of 3D Printers Printing Themselves

1. Technological Evolution: The ability of 3D printers to self-replicate opens up a whole new realm of technological advancement. It could pave the way for exponential growth in manufacturing, design, and innovation.

2. Sustainability: Self-replicating 3D printers have the potential to revolutionize the concept of recycling and reducing waste.

Imagine being able to recycle old or broken products by simply feeding them into a 3D printer, which then transforms them into new and useful items. Mother Earth would definitely give us a high-five for that!

3. Unleashing Creativity: When the barriers to manufacturing are lowered, individuals and businesses can unleash their creative potential like never before.

The power to bring ideas to life, without the limitations of traditional manufacturing processes, can spark a wave of innovation that ripples across industries.

So, my friends, the future is looking mighty bright with the possibility of 3D printers printing themselves.

It’s a mind-bending concept that could reshape the way we create, produce, and consume. The question is, are you ready to embrace this brave new world?

II. Advantages of 3D Printers Printing Other 3D Printers

When it comes to the world of 3D printing, the idea of a printer being able to print another printer might seem like something out of a science fiction movie.

However, this concept is not only possible but also comes with a range of advantages that can revolutionize the field of manufacturing. Here, I will discuss some of the key advantages of 3D printers being able to print other 3D printers.

1. Cost Efficiency

One of the major advantages of 3D printers printing other 3D printers is the potential for cost efficiency.

Traditionally, manufacturing a 3D printer involves complex and expensive processes, including sourcing materials, assembling components, and testing.

However, if a 3D printer can replicate itself, the need for external manufacturing processes is significantly reduced.

This can lead to a significant reduction in production costs, making 3D printers more accessible and affordable for individuals and businesses alike.

2. Increased Accessibility

By enabling 3D printers to print other 3D printers, the accessibility of this technology can be greatly enhanced. Currently, 3D printers are primarily used in industrial settings or by enthusiasts who have the knowledge and resources to operate them.

However, if 3D printers become capable of self-replication, it opens up the possibility for more people to have access to this technology. This can lead to a democratization of manufacturing, allowing individuals to create their own products and prototypes with ease.

3. Rapid Prototyping

Another advantage of 3D printers printing other 3D printers is the potential for rapid prototyping. In traditional manufacturing processes, creating a prototype can be time-consuming and expensive.

However, with self-replicating 3D printers, the process of prototyping can be significantly accelerated.

This means that designers and engineers can iterate and test their designs more quickly, leading to faster innovation and product development cycles.

4. Scalability

Self-replicating 3D printers also offer the advantage of scalability. With traditional manufacturing methods, scaling up production can be a complex and costly process.

However, if 3D printers can print other 3D printers, the scalability of manufacturing becomes much easier.

It allows for the rapid expansion of production capacity without the need for additional resources or infrastructure.

This can be particularly beneficial for small businesses or startups that need to quickly ramp up their production to meet growing demand.

5. Sustainability

Lastly, self-replicating 3D printers have the potential to contribute to a more sustainable manufacturing industry. Traditional manufacturing processes often result in significant waste and carbon emissions.

However, if 3D printers can print other 3D printers, it reduces the need for external manufacturing processes and transportation, thereby minimizing the environmental impact.

Additionally, 3D printing enables more efficient use of materials, as it only uses the exact amount needed for each print, reducing waste even further.

Summary

As the field of 3D printing continues to advance, the possibility of 3D printers printing themselves opens up a world of opportunities.

The advantages of self-replicating 3D printers, including cost efficiency, increased accessibility, rapid prototyping, scalability, and sustainability, are significant and have the potential to transform the manufacturing industry.

By harnessing this technology, we can unlock new possibilities and drive innovation in ways that were previously unimaginable.

III. Challenges and Limitations in 3D Printing a 3D Printer

While the idea of 3D printers printing other 3D printers may seem revolutionary and exciting, there are several challenges and limitations that need to be addressed before this concept can become a reality.

1. Complexity of Components

One of the main challenges in 3D printing a 3D printer is the complexity of its components. A 3D printer is composed of various intricate parts such as motors, sensors, circuit boards, and wiring.

Ensuring that all these components can be accurately reproduced by a 3D printer requires advanced technology and precise calibration.

2. Material Limitations

Another limitation is the availability of suitable materials for 3D printing a 3D printer.

Currently, most consumer-grade 3D printers use plastic filament as the primary material.

However, plastic may not be the most suitable material for printing complex components, especially those that require high strength or conductivity.

Developing new materials that are compatible with 3D printing and can meet the requirements of a functional 3D printer is an ongoing challenge.

3. Assembly and Calibration

Once all the components are printed, the assembly and calibration process poses another challenge.

A 3D printer needs to be assembled with precision to ensure proper alignment and functionality.

Additionally, calibration is crucial to fine-tune the printer’s settings and ensure accurate printing.

Developing automated assembly and calibration processes that can be replicated by a 3D printer is a complex task that requires extensive research and development.

4. Quality Control

Quality control is a significant concern when it comes to 3D printing a 3D printer.

Ensuring that the printed components meet the required specifications and tolerances is essential for the printer’s overall performance.

Implementing quality control measures during the printing process, such as real-time monitoring and feedback systems, is necessary to identify and rectify any issues that may arise.

This requires advanced algorithms and software integration to ensure consistent and reliable printing results.

5. Cost and Efficiency

Lastly, the cost and efficiency of 3D printing a 3D printer are important factors to consider. The process of printing a 3D printer may require a significant amount of time and resources.

The cost of materials, energy consumption, and maintenance should be taken into account to determine the feasibility and affordability of this approach.

Improving the efficiency of the printing process and optimizing resource utilization are ongoing challenges that need to be addressed to make 3D printers printing themselves a practical and cost-effective solution.

IV. The Future Implications of 3D Printers Printing Themselves

As we delve into the world of 3D printing, the concept of 3D printers being able to print themselves opens up a whole new realm of possibilities.

The idea of self-replicating machines may seem like something out of a science fiction movie, but with advancements in technology, it is becoming a reality.

One of the most significant implications of 3D printers printing themselves is the potential for exponential growth in the manufacturing industry.

With self-replicating machines, the production of 3D printers can be accelerated, leading to a rapid increase in their availability and affordability.

This, in turn, can revolutionize various sectors such as healthcare, aerospace, automotive, and consumer goods.

By enabling 3D printers to reproduce themselves, we can reduce the reliance on traditional manufacturing processes and their associated costs. This could lead to a more sustainable and efficient production system, as fewer resources would be needed to manufacture new printers.

Additionally, the ability to quickly replace or upgrade parts of a printer by printing them on-site can significantly reduce downtime and increase productivity.

Moreover, the self-replication capability of 3D printers opens up possibilities for remote and autonomous manufacturing.

Imagine a scenario where a 3D printer can reproduce itself in a remote location, such as a space station or a remote village, without the need for human intervention.

This could bring manufacturing capabilities to areas that were previously inaccessible, leading to economic growth and development.

However, it is important to acknowledge the challenges and limitations that come with 3D printers printing themselves. Ensuring the quality and accuracy of the replicated printers is crucial to avoid any flaws or malfunctions in the production process.Additionally, the availability of suitable materials for printing the various components of a printer can be a limiting factor.

The future implications of 3D printers printing themselves are vast and exciting.

From revolutionizing manufacturing processes to enabling remote and autonomous manufacturing, the self-replication capability of 3D printers has the potential to reshape industries and create new opportunities.

As technology continues to advance, we can expect to see further developments in this field, unlocking even more possibilities for the future of manufacturing.

Frequently Asked Questions Can a 3D Printer Really Print Another 3D Printer

1. Can a 3D printer really print another 3D printer?

Yes, it is possible for a 3D printer to print certain parts of another 3D printer. However, not all components can be printed, as some require electronic components and motors that cannot be replicated by a 3D printer.

2. How does a 3D printer print itself?

A 3D printer can print its own components by using a process called additive manufacturing. The printer follows a digital design file and deposits layers of material, such as plastic or metal, to gradually build up the desired shape.

3. Are there any limitations to printing a 3D printer?

Yes, there are limitations to printing a 3D printer. While the structural parts can be printed, certain components like motors, wiring, and electronic circuitry need to be manually installed. Additionally, the printer’s firmware and software cannot be printed and must be separately programmed.

4. Can any 3D printer print another 3D printer?

No, not all 3D printers are capable of printing another 3D printer. The printer needs to have a large enough build volume and be able to handle the required materials for the parts. Some printers may also lack the necessary precision or resolution to print intricate components.

5. Are there any specific designs available for printing a 3D printer?

Yes, there are open-source designs available for printing 3D printers, such as the RepRap project. These designs provide a starting point for building a printer and can be modified or customized to suit individual needs.

6. How long does it take to print a 3D printer?

The printing time for a 3D printer can vary depending on the complexity of the components and the printer’s speed. It can take anywhere from several hours to several days to complete the printing process.

7. What materials are commonly used to print a 3D printer?

Common materials used to print 3D printers include various types of plastic, such as PLA (polylactic acid) and ABS (acrylonitrile butadiene styrene). Some printers also utilize metal powders or resins for more advanced applications.

8. Can a 3D printer print all the parts needed for its own assembly?

No, a 3D printer cannot print all the parts needed for its own assembly. As mentioned earlier, certain components like motors and electronic circuitry need to be sourced separately and manually installed.

9. Is it cost-effective to print a 3D printer?

Printing a 3D printer can be cost-effective compared to purchasing a pre-assembled one. However, it is important to consider the cost of materials, time, and any additional components required. DIY enthusiasts may find it more economical, while others may prefer the convenience of buying a ready-made printer.

10. Can a 3D printer continuously print multiple 3D printers?

Technically, a 3D printer can continuously print multiple 3D printers. However, it is important to consider factors such as material availability, cooling time, and maintenance requirements. It may not be practical to continuously print multiple printers without interruptions.

Wrapping Up: Can a 3D Printer Really Print Another 3D Printer

Yes, a 3D printer can indeed print another 3D printer. This revolutionary technology has made it possible to replicate complex objects, including itself.

By using the right materials and designs, a 3D printer can produce the necessary components and assemble them into a functional 3D printer.

This self-replicating capability opens up endless possibilities for the manufacturing industry and allows for rapid prototyping and customization.

With advancements in 3D printing technology, we can expect to see even more sophisticated and efficient 3D printers being printed in the future.