Yes, a printer can print white.

However, it requires a specialized printer that uses a different technique called “white ink printing” or “white toner printing” to achieve this.

Traditional printers use a subtractive color model and do not have white ink in their cartridges, so they cannot directly print white.

White ink printing is commonly used for printing on dark or transparent materials, creating unique and eye-catching designs.

I. The Benefits of White Printing

White printing, also known as reverse printing or underprinting, is a technique that offers a myriad of benefits for various applications. In this article, I will delve into the advantages of white printing and shed light on its diverse uses.

Enhanced Visibility and Vibrancy

One of the key advantages of white printing is its ability to make colors pop. By printing a layer of white ink beneath the colors, it creates a solid foundation that enhances the vibrancy and visibility of the design.

This is particularly beneficial when working with transparent or dark materials, as the white ink acts as a base to ensure the colors stand out.

Unleash Creativity

White printing opens up a whole new world of creative possibilities. With the ability to print on colored or textured substrates, it allows designers to experiment with unique effects and create eye-catching designs.

Whether it’s adding a white pattern to a dark background or incorporating white text on a colored surface, the versatility of white printing knows no bounds.

Brand Consistency and Elegance

For businesses and organizations, maintaining brand consistency is vital. White printing provides a way to ensure that your brand’s colors remain consistent across different materials and substrates.

By underprinting with white ink, you can achieve a consistent color appearance, regardless of the material’s color or texture.

This not only enhances your brand’s recognition but also adds a touch of elegance to your printed materials.

Cost-Effective Solution

White printing offers a cost-effective solution for achieving premium results. Instead of using expensive colored substrates or specialty inks, white printing allows you to achieve the desired effects using standard materials and inks.

This can significantly reduce production costs while still delivering high-quality results.

Applications of White Printing

The applications of white printing are vast and diverse. It is commonly used in packaging design, where it can add a luxurious touch to product boxes or labels.

Additionally, white printing is widely employed in the fashion industry for printing on textiles and garments. It can also be utilized in signage, promotional materials, and even fine art prints.

White printing offers a range of benefits, from enhancing visibility and creativity to ensuring brand consistency and cost-effectiveness.

With its versatility and wide range of applications, it is a valuable technique for designers and businesses alike. So, why not explore the world of white printing and unlock its full potential?

II. Challenges of White Printing

Let me tell you, folks, white printing may seem like a walk in the park, but it comes with its fair share of challenges.

Don’t you worry, though, because I’ve got your back. I’m here to break it down for you and give you the lowdown on the hurdles you might face when it comes to white printing.

The Color Conundrum

One of the biggest challenges you’ll encounter with white printing is dealing with the color conundrum.

You see, when you print on a dark or colored surface, getting that crisp white color to pop can be quite the task. It’s like trying to find a needle in a haystack, my friends.

But fear not! There are techniques and tricks that can help you overcome this challenge. From using specialized inks to adjusting print settings, you’ll be able to achieve that vibrant white color you desire.

Opaque or Not?

Another challenge that might come knocking on your door is the issue of opacity. You want your white print to stand out, but sometimes it ends up looking a bit transparent, like a ghost in the night. That’s not the look you’re going for, right?

Well, worry not, because there are ways to tackle this challenge head-on.

You can experiment with different layers of white ink or try out different printing techniques to achieve the desired level of opacity. It’s all about finding the right balance, my friends.

Compatibility Concerns

Now, let’s talk about compatibility concerns. You might encounter some hiccups when it comes to printing white on certain materials or surfaces. It’s like trying to fit a square peg into a round hole, and we all know that’s no easy feat.

But fret not, my friends, for there are techniques you can employ to overcome this challenge.

From pre-treating the surface to using special primers, you’ll be able to ensure that your white printing endeavors are compatible with a wide range of materials.

Finishing Frustrations

Last but not least, we have the finishing frustrations. You’ve put in all the hard work to get that white print just right, but then comes the finishing stage, and things can go haywire.

It’s like trying to catch a slippery fish with your bare hands, my friends.

But don’t lose hope! There are ways to tackle this challenge and achieve that flawless finish.

From using protective coatings to experimenting with different curing methods, you’ll be able to ensure that your white prints not only look great but also stand the test of time.

So there you have it, folks! The challenges of white printing laid bare.

But remember, with the right techniques and a bit of perseverance, you can overcome these hurdles and create stunning white prints that will leave everyone in awe.

III. Techniques for White Printing

When it comes to white printing, there are several techniques that can be used to achieve the desired results. These techniques are crucial in ensuring that the white ink stands out and provides the desired effect.

Below, I will discuss some of the most commonly used techniques for white printing.

Digital White Printing

Digital white printing is a popular technique that involves using a digital printer to apply white ink onto various surfaces.

This technique is highly versatile and can be used on a wide range of materials, including paper, cardstock, and even fabrics.

Digital white printing offers precise and accurate results, making it an excellent choice for detailed designs and intricate patterns.

Screen Printing

Screen printing is another technique commonly used for white printing. This technique involves creating a stencil, also known as a screen, and using it to apply white ink onto the desired surface.

Screen printing is often used for larger print runs and is known for its durability and longevity. It can be used on various materials, including paper, plastics, and textiles.

Offset Printing

Offset printing is a traditional printing technique that can also be used for white printing. This technique involves transferring the image or design onto a rubber blanket, which is then pressed onto the surface to be printed.

Offset printing is known for its high-quality results and is often used for professional printing projects. It is suitable for a wide range of materials, including paper, cardboard, and metal.

UV Printing

UV printing is a modern technique that uses ultraviolet (UV) light to cure the ink instantly. This technique allows for quick drying and ensures that the white ink remains vibrant and opaque.

UV printing is often used for printing on non-absorbent materials, such as glass, metal, and plastic. It offers excellent color saturation and is ideal for printing high-resolution images and graphics.

Pad Printing

Pad printing is a versatile technique that can also be used for white printing. This technique involves transferring the ink from a silicone pad onto the desired surface.

Pad printing is commonly used for printing on irregularly shaped objects, such as promotional items and electronic devices. It offers precise and consistent results, making it suitable for intricate designs and small print runs.

Overall, these techniques for white printing offer a range of options for achieving the desired results.

Whether you need to print on paper, plastics, fabrics, or even glass, there is a technique that can meet your needs.

By understanding the different techniques available, you can choose the most appropriate method for your specific project.

IV. Applications of White Printing

White printing has a wide range of applications in various industries. Its versatility and ability to add a unique touch to printed materials make it a popular choice for many businesses.

Here are some of the common applications of white printing:

1. Packaging and Labels

White printing is often used in packaging and labels to create eye-catching designs.

It can be used to print logos, product information, and decorative elements on boxes, bags, bottles, and other packaging materials.

The white ink stands out on colored or transparent surfaces, making the packaging more visually appealing and helping products to stand out on store shelves.

2. Promotional Materials

White printing is also commonly used in the production of promotional materials such as brochures, flyers, and business cards.

By incorporating white ink into the design, businesses can create a more visually striking and memorable marketing collateral.

The white ink can be used to highlight important information, add texture, or create a unique design element that sets the promotional materials apart from others.

3. Signage and Displays

White printing is widely used in the production of signage and displays. It can be used to print text, logos, and graphics on various materials such as acrylic, glass, metal, or wood.

The white ink provides excellent visibility and contrast, making the signage and displays easy to read and visually appealing.

This makes white printing a popular choice for retail stores, restaurants, exhibitions, and trade shows.

4. Wedding Invitations and Stationery

White printing is a popular choice for wedding invitations and stationery due to its ability to add an elegant and sophisticated touch.

It can be used to print intricate designs, patterns, or monograms on cards, envelopes, and other stationery items.

The white ink creates a beautiful contrast on colored or textured paper, making the wedding invitations and stationery more visually appealing and personalized.

5. Art and Photography Prints

White printing is also used in the art and photography industry to create high-quality prints. It can be used to reproduce artwork, photographs, or digital designs on various materials such as canvas, paper, or metal.

The white ink helps to enhance the details, highlights, and shadows in the prints, resulting in stunning and visually captivating reproductions.

6. Textile and Fashion Industry

White printing is commonly used in the textile and fashion industry to create unique and fashionable designs on fabrics. It can be used to print patterns, logos, or decorative elements on garments, accessories, or home textiles.

The white ink provides excellent opacity and color vibrancy, allowing designers to create visually striking and personalized textile products.

7. Interior Design and Decor

White printing is also utilized in the field of interior design and decor. It can be used to print designs, patterns, or artwork on various surfaces such as walls, furniture, or home decor items.

The white ink adds a touch of elegance and creativity to the interior space, transforming it into a visually appealing and unique environment.

White printing offers a multitude of applications across different industries.

Its ability to create visually striking designs, enhance visibility, and add a unique touch to printed materials makes it a valuable tool for businesses and individuals alike.

Can a Printer Print White – FAQ

1. Can a printer print white ink?

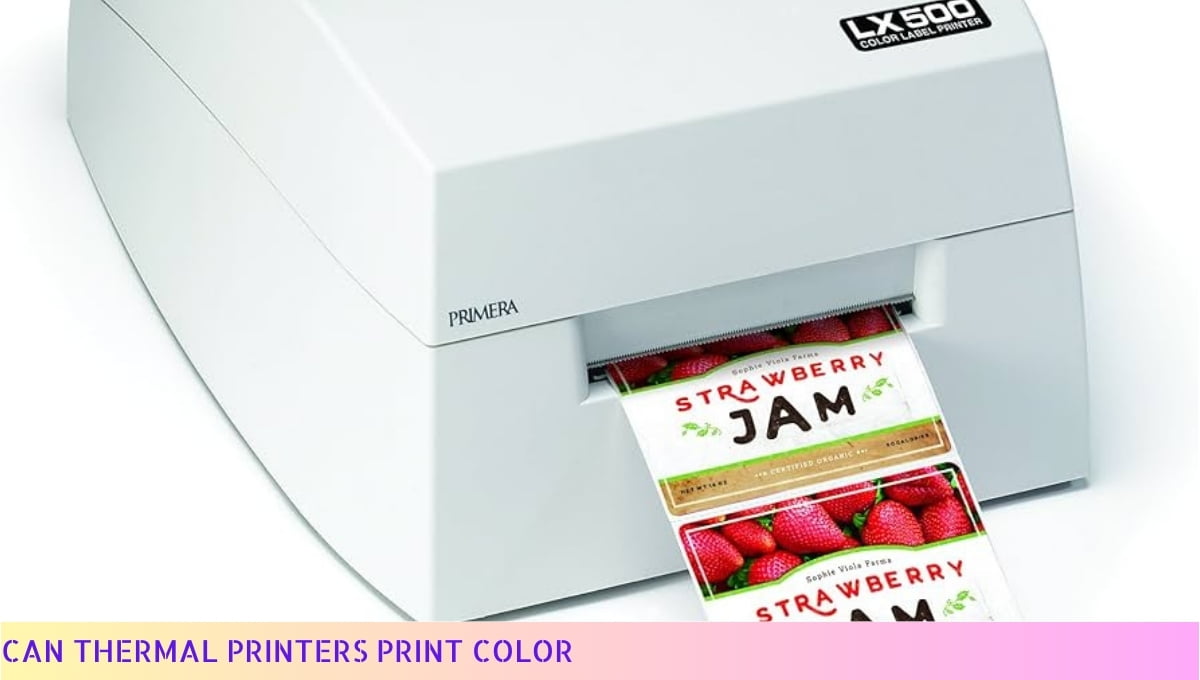

Yes, certain printers have the capability to print white ink. These printers are commonly used in industries such as graphic design, signage, and textile printing.

2. How does a printer print white?

Printers that can print white ink use a specialized process where white ink is applied as an additional layer on top of other colors. This allows the printer to create a white base for printing on dark or transparent materials.

3. What types of printers can print white?

Typically, specialized printers such as UV printers, screen printers, and some digital printers have the ability to print white ink. These printers are designed specifically for applications that require white ink printing.

4. Can regular inkjet printers print white?

No, regular inkjet printers do not have the capability to print white ink. They are designed to mix the colors of ink to create different shades, but they cannot produce a true white color.

5. What are the applications of white ink printing?

White ink printing is commonly used in various applications such as printing on dark-colored materials, creating highlights and textures on artwork, printing on transparent surfaces like window decals, and adding a base layer for vibrant color reproduction.

6. Can white ink be used on any type of material?

White ink can be used on a wide range of materials including paper, cardboard, fabric, plastics, glass, and metal. However, the compatibility of white ink with a specific material may depend on the printer and ink formulation being used.

7. Is white ink printing more expensive?

White ink printing can be more expensive compared to regular printing because it requires additional ink and printing processes. The cost may vary depending on the printer, ink type, and the complexity of the design.

8. Are there any limitations to white ink printing?

Yes, there are some limitations to white ink printing. It may require multiple layers of ink to achieve opacity, which can increase printing time. Additionally, some printers may have limitations on the size or thickness of materials that can be printed with white ink.

9. Can white ink be used for printing text?

Yes, white ink can be used for printing text. It can create a unique and eye-catching effect when used for text or logos on dark-colored materials.

10. Can I convert my existing printer to print white ink?

No, converting a regular printer to print white ink is not possible. It requires specialized hardware and ink systems that are specifically designed for white ink printing.

Conclusion:

It is not possible for a printer to directly print the color white. Traditional printers use a combination of subtractive color mixing, where colors are created by subtracting light wavelengths, and they rely on the white paper as the base color.

However, there are specialized printers available that can print white ink on dark or colored surfaces, but they achieve this by using an additional process like screen printing or using white toner.

So, while a printer cannot print white by itself, there are alternative methods to achieve white printing on specific materials or surfaces.