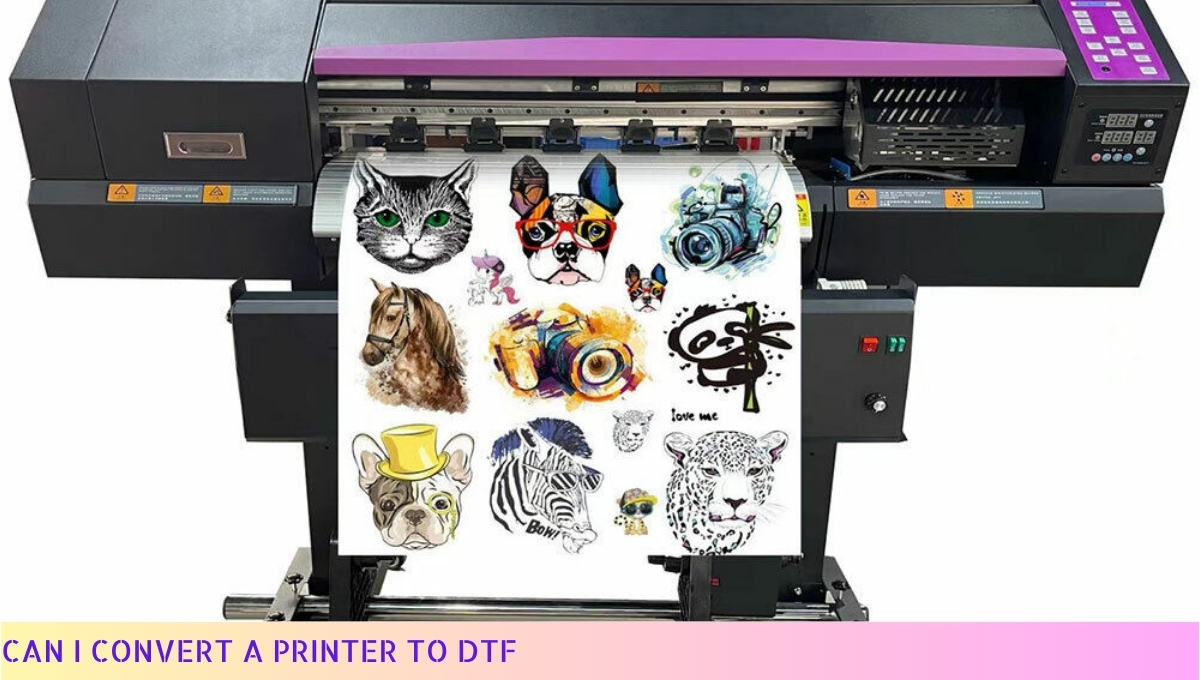

Yes, it is possible to convert a printer to DTF (Direct to Film) printing.

DTF printing is a process where ink is directly transferred onto a film, which can then be used to create screen prints on various surfaces.

To convert a printer, you would need to install a DTF conversion kit, which typically includes specialized inks, a modified printhead, and software adjustments.

It’s important to note that not all printers are compatible with DTF conversion, so it’s best to consult with a professional or the printer manufacturer for specific instructions.

I. Benefits of Converting a Printer to DTF

Converting a printer to DTF (Direct-to-Film) can offer a range of benefits that will make your printing game stronger than ever. Let me break it down for you, my friend.

First off, DTF printing allows you to expand your creativity and explore new horizons.

With the ability to print on a variety of materials, such as fabric, leather, and even wood, you can bring your designs to life in ways you never thought possible. Say goodbye to limitations and hello to endless possibilities!

Not only does DTF printing give you the freedom to experiment with different materials, but it also produces vibrant and long-lasting prints.

The colors will pop like fireworks on the Fourth of July, capturing the attention of anyone who lays eyes on your creations.

Whether you’re printing t-shirts, posters, or custom artwork, DTF will ensure that your designs stand out from the crowd.

Another fantastic advantage of converting your printer to DTF is the cost-effectiveness. Unlike traditional printing methods, DTF printing eliminates the need for costly screens or plates.

Say goodbye to those hefty expenses, my friend! With DTF, you can print small quantities without breaking the bank, making it perfect for personalized or on-demand printing.

Now that we’ve covered the benefits, let’s dive into the steps to convert your printer to DTF. But before we do that, remember, my friend, to always do your research and consider a few important factors.

Remember, always stay curious and keep exploring new possibilities. Happy printing, my friend!

II. Steps to Convert a Printer to DTF

So, you’re ready to take the plunge and convert your printer to DTF (Direct-to-Film) printing? Awesome! Let’s dive right in and go through the step-by-step process to get you started.

Gather the Necessary Materials

Before we begin, make sure you have all the tools and materials you’ll need. This includes a compatible printer, DTF ink, DTF film, a heat press machine, and a computer with the necessary software.

Prepare Your Printer

First things first, you’ll need to prepare your printer for the conversion. This may involve removing any existing ink cartridges, cleaning the printhead, and ensuring that the printer is in good working condition.

Install the DTF Ink System

Now comes the exciting part – installing the DTF ink system. Follow the manufacturer’s instructions carefully to ensure a proper installation.

This usually involves connecting ink tubes to the printer’s ink supply, installing DTF ink cartridges, and priming the system.

Load the DTF Film

Next, load the DTF film into your printer. Make sure to adjust the paper guides to fit the width of the film and ensure it is properly aligned. This will help prevent any printing mishaps and ensure high-quality results.

Prepare Your Design

Using your computer and the necessary software, create or import the design you want to print. Make any necessary adjustments to the size, resolution, and colors to ensure optimal printing results.

Print and Cure

Now it’s time to print your design onto the DTF film. Send the print command from your computer to the printer, making sure all the settings are correct.

Once the printing is complete, carefully remove the DTF film from the printer and place it on the heat press machine.

Apply the necessary heat and pressure according to the manufacturer’s recommendations to cure the ink onto the film. This step is crucial for achieving vibrant and long-lasting prints.

Transfer the Design

After the curing process, it’s time to transfer your design onto the desired substrate.

This could be a t-shirt, hoodie, or any other fabric or material suitable for DTF printing.

Place the DTF film face down onto the substrate and apply heat and pressure once again to transfer the ink.

Peel and Enjoy

Once the transfer is complete, carefully peel off the DTF film to reveal your beautifully printed design. Admire your work, and don’t forget to give yourself a pat on the back for successfully converting your printer to DTF!

Now that you have the know-how, you’re all set to embark on your DTF printing journey. Remember, practice makes perfect, so don’t be discouraged if your first prints aren’t flawless.

Keep experimenting, honing your skills, and soon enough, you’ll be creating stunning DTF prints like a pro!

III. Considerations Before Converting a Printer to DTF

Before you take the leap and convert your printer to DTF (Direct-to-Film), there are a few important considerations to keep in mind.

This conversion process can offer numerous benefits, but it’s essential to evaluate whether it’s the right choice for you and your printing needs. So, let’s dive in and explore the key factors to consider:

1. Printer Compatibility:

Not all printers are compatible with DTF conversion. It’s crucial to check if your printer model supports the necessary modifications.

Research the specific requirements and ensure that your printer is capable of handling the DTF process effectively.

2. Cost Analysis:

Converting a printer to DTF involves some upfront costs. You’ll need to invest in specialized equipment, such as DTF ink, film, and heat press machinery.

Additionally, consider the ongoing expenses, such as maintenance, ink refills, and film replacements. It’s essential to conduct a cost analysis and determine if the long-term benefits outweigh the initial investment.

3. Printing Volume:

Assess your printing volume and workload. DTF printing is most beneficial for businesses or individuals with a high demand for customized prints.

If you frequently require high-quality prints on various materials, such as fabrics, wood, or metal, DTF conversion might be a suitable option.

However, if your printing needs are minimal or infrequent, it may not be cost-effective to undergo the conversion process.

4. Learning Curve:

Converting a printer to DTF involves acquiring new skills and knowledge. Familiarize yourself with the DTF process, including the proper handling of DTF ink, film, and heat press equipment.

Be prepared to invest time in training and learning the best practices for achieving optimal results. If you’re not willing to commit to the learning curve, it may be better to explore other printing methods.

5. Quality and Durability:

Consider the quality and durability of the prints you aim to achieve. DTF printing offers vibrant colors, fine details, and excellent washability on various materials.

However, it’s crucial to test and evaluate the print quality before committing to the conversion. Ensure that the DTF prints meet your expectations in terms of color accuracy, sharpness, and longevity.

6. Support and Resources:

Research the availability of support and resources for DTF printing. Join online communities, forums, or social media groups to connect with experienced DTF printers who can offer guidance and troubleshooting tips.

Having access to a supportive network can be invaluable, especially during the initial stages of the conversion process.

By considering these factors, you can make an informed decision about whether converting your printer to DTF is the right move for you.

Remember, it’s crucial to weigh the pros and cons, assess your specific requirements, and evaluate the long-term benefits before embarking on this conversion journey.

IV. Troubleshooting Common Issues when Converting a Printer to DTF

So, you’ve taken the plunge and decided to convert your printer to DTF (Direct-to-Film) printing.

Kudos to you for embracing this exciting technology! But, as with any new endeavor, you might encounter a few bumps along the way.

Don’t worry, though—I’ve got your back. Let’s delve into some common issues you might face during the conversion process and how to troubleshoot them like a pro.

Ink Compatibility

One of the first things you need to consider is ink compatibility. Not all printers are created equal, and not all inks work harmoniously with the DTF method. Make sure you’re using the right ink for your printer model and the DTF process.

Consult your printer manufacturer’s guidelines or reach out to their customer support for recommendations. Using incompatible inks can result in poor print quality or even damage to your printer, and we definitely don’t want that!

Print Head Clogs

Ah, the dreaded print head clogs. These little devils can wreak havoc on your DTF printing journey. If you notice uneven or missing lines in your prints, it’s likely that your print head is clogged.

Fear not, my friend, for there’s a simple fix. Start by running a print head cleaning cycle through your printer’s software.

This should help unclog any dried ink particles. If the problem persists, you might need to manually clean the print head using a cleaning solution or seek professional assistance.

Film Feeding Issues

Sometimes, the film just doesn’t want to cooperate. It might get jammed or fail to feed properly, leading to frustrating print failures. The culprit here could be a misaligned or dirty film feeding mechanism.

Check if the film guides are aligned correctly and free from any debris. Clean them gently if needed. Additionally, make sure you’re using high-quality film that’s suitable for DTF printing.

Cheap or incompatible film can cause feeding issues. Remember, a smooth film feed equals crisp prints!

Color Inconsistencies

Color inconsistencies can be a real headache, especially when you’re striving for vibrant and accurate prints. If you notice variations in color intensity or hue, check your ink settings.

Ensure that your printer is calibrated properly and that you’re using the correct color profiles. Additionally, double-check your color management settings in your graphic design software.

Making these adjustments should help you achieve consistent and true-to-life colors in your DTF prints.

Maintenance and Upkeep

Last but not least, don’t forget about regular maintenance and upkeep. Like any machine, your converted DTF printer requires some TLC to keep performing at its best. Clean the printer regularly, following the manufacturer’s guidelines.

Replace any worn-out parts or consumables as needed. By keeping your printer in tip-top shape, you’ll minimize the chances of encountering issues down the road.

Remember, my friend, troubleshooting is all about being patient, observant, and willing to experiment. Don’t be afraid to seek help from online forums or professional technicians if you’re stuck.

With perseverance and a little know-how, you’ll conquer any challenges that come your way on your DTF printing journey. Happy printing, and may your DTF prints be flawless and fabulous!

FAQs: Converting a Printer to DTF

1. Can I convert any printer to DTF?

Yes, most printers can be converted to DTF (Direct-to-Film) printing with the right modifications and equipment.

2. What is DTF printing?

DTF printing is a technique that allows you to directly print designs onto a special film, which can then be transferred onto various surfaces.

3. What modifications are required to convert a printer to DTF?

Converting a printer to DTF typically involves installing a specialized ink delivery system, adding a film attachment mechanism, and making adjustments to the printer settings.

4. Can I convert an inkjet printer to DTF?

Yes, inkjet printers are commonly used for DTF printing. However, certain models may require specific modifications or additional components.

5. Is converting a printer to DTF a DIY project?

While it is possible to convert a printer to DTF on your own, it is recommended to seek professional assistance or guidance to ensure proper installation and functionality.

6. Are there any risks involved in converting a printer to DTF?

Converting a printer to DTF may void its warranty and could potentially damage the printer if not done correctly. It is important to follow proper instructions and seek expert advice.

7. Can I switch back to regular printing after converting a printer to DTF?

Yes, in most cases, you can switch back to regular printing by removing the DTF conversion components and reverting the printer settings to their original configuration.

8. Is DTF printing suitable for all types of designs?

DTF printing is versatile and can accommodate various designs, including complex and multi-colored ones. However, it is recommended to consult with a professional to ensure optimal results.

9. What are the advantages of DTF printing?

DTF printing offers advantages such as vibrant and durable prints, the ability to print on different surfaces, and the flexibility to produce customized designs quickly.

10. Are there any limitations to DTF printing?

While DTF printing is versatile, it may have limitations in terms of print size, texture compatibility, and certain fabric types. Consulting with a professional can help determine suitability for specific applications.

Wrapping Up

So, can you convert a printer to DTF? Well, the answer is both yes and no. While it is technically possible to modify a printer to work with DTF printing, it requires specialized knowledge, equipment, and expertise.

It’s not a simple DIY project that you can tackle on your own. If you’re serious about DTF printing, it’s best to invest in a dedicated DTF printer that is specifically designed for this purpose.

This way, you can ensure optimal performance, high-quality prints, and a seamless printing experience. Don’t compromise on quality, go for the real deal!