No, you cannot use a regular printer for sublimation printing.

Regular inkjet printers use dye-based inks that do not bond with polyester materials during the sublimation process.

Sublimation requires specific sublimation inks and printers designed to handle them, as they convert ink into gas when heated, allowing for vibrant, permanent designs on polyester fabrics and coated surfaces.

Investing in a dedicated sublimation printer ensures quality results and longevity of your prints.

Can You Use a Regular Printer for Sublimation?

As someone who has explored various printing techniques, I often get asked whether a regular printer can be used for sublimation. The answer is nuanced, so let’s unpack it together.

Understanding Sublimation Printing

Sublimation printing is a unique process that allows for vibrant, long-lasting prints on various materials, primarily polyester or polymer-coated substrates.

The technique involves turning solid dye into gas without passing through a liquid state, which then bonds with the fabric or material, creating a durable image.

This method is favored for its ability to produce stunning colors and intricate designs that stand the test of time.

Regular Printers vs. Sublimation Printers

Regular printers, typically inkjet or laser printers, use different technologies and inks compared to sublimation printers.

While regular printers can produce high-quality images, they lack the specific capabilities required for sublimation.

Here’s a breakdown of the differences:

- Ink Type: Regular printers use standard ink, while sublimation printers utilize dye-sublimation inks that turn into gas when heated.

- Printing Process: Sublimation printers have specialized print heads and heating elements that facilitate the dye transfer process, which regular printers do not possess.

- Material Compatibility: Regular printers can print on a variety of papers, but sublimation requires specific polyester-coated materials for the best results.

Can You Modify a Regular Printer for Sublimation?

While it’s theoretically possible to convert a regular printer for sublimation use, I strongly advise against it for several reasons:

- Ink Compatibility: Regular printers are not designed to handle sublimation inks. Attempting to use them may lead to clogs and damage to the print head.

- Heat Settings: Sublimation requires specific heat settings to transfer the dye effectively. Regular printers lack the necessary temperature control features.

- Quality Issues: Even if you manage to modify a regular printer, the quality of the prints may not meet the standards you desire.

What Are Your Options?

If you’re serious about sublimation printing, investing in a dedicated sublimation printer is your best bet.

These printers are specifically designed for the process and will yield the best results. However, if you want to experiment with sublimation without breaking the bank, here are a few options to consider:

- Buy a Second-Hand Sublimation Printer: This can be a cost-effective way to get into sublimation without spending a fortune on a new model.

- Look for Entry-Level Sublimation Printers: Many brands offer affordable options that are user-friendly and perfect for beginners.

- Consider Hybrid Printers: Some printers are designed to handle both regular and sublimation printing, giving you flexibility without sacrificing quality.

Conclusion

In summary, while you might be tempted to use a regular printer for sublimation, it’s not advisable due to the technical differences and potential quality issues.

Investing in a sublimation printer will save you time and frustration in the long run, ensuring that your projects turn out beautifully.

Pros and Cons of Using a Regular Printer for Sublimation

As someone who’s explored the world of sublimation printing, I understand the importance of weighing your options.

If you’re considering using a regular printer for sublimation, it’s crucial to evaluate both the advantages and disadvantages before making a decision.

Pros of Using a Regular Printer for Sublimation

Using a regular printer for sublimation can offer several benefits, especially if you’re just starting out or looking to save some money.

Here are some of the key advantages:

- Cost-Effective: Regular printers are generally less expensive than dedicated sublimation printers. If you already own one, it can be a budget-friendly way to experiment with sublimation printing.

- Availability: Regular printers are widely available, making it easy to find replacement parts or supplies. This accessibility can be a significant advantage, especially if you need to troubleshoot or upgrade your equipment.

- Versatility: Many regular printers can handle various types of media, allowing you to print not just sublimation designs but also standard prints, photos, and other projects. This versatility can be beneficial if you have diverse printing needs.

- Familiarity: If you are already accustomed to using a regular printer, transitioning to sublimation can be less intimidating. You’ll already understand the basic operations, making it easier to adapt.

Cons of Using a Regular Printer for Sublimation

While there are advantages, there are also some significant drawbacks to consider when using a regular printer for sublimation printing:

- Ink Compatibility: Regular printers use dye-based or pigment inks, which are not suitable for sublimation. Sublimation requires special inks that turn into gas when heated, embedding the design into the substrate. If you attempt to use a regular printer, you will not achieve the vibrant results you desire.

- Print Quality: Regular printers may not be able to produce the same level of detail and color vibrancy as dedicated sublimation printers. This can lead to unsatisfactory results, especially for high-quality projects.

- Printhead Issues: Using a regular printer for sublimation can lead to clogging and damage to the printhead if you use sublimation inks. Regular printers are not designed to handle the chemical composition of sublimation inks, which can lead to costly repairs.

- Limited Substrate Options: Sublimation printing works best on polyester-coated materials. Regular printers may not be able to handle the specialized substrates required for sublimation, limiting your printing options.

Additional Considerations

When weighing the pros and cons, here are some additional factors to keep in mind:

- Long-Term Costs: While using a regular printer may save you money upfront, consider the long-term costs of potential repairs or the need to eventually invest in a dedicated sublimation printer.

- Learning Curve: Even if you are familiar with your regular printer, sublimation has its own set of techniques and requirements. Be prepared for a learning curve as you adapt your process.

- Project Goals: Think about the types of projects you plan to undertake. If you’re focused on high-quality sublimation work, investing in a dedicated printer might be more beneficial in the long run.

Ultimately, the decision to use a regular printer for sublimation depends on your specific needs and goals.

If you are just exploring the possibilities and want to keep costs low, it might be worth experimenting with what you have.

However, if you are serious about sublimation printing and want to achieve professional-quality results, investing in a dedicated sublimation printer is likely the better choice.

Tips for Using a Regular Printer for Sublimation

As someone who’s navigated the world of printing, I understand the curiosity surrounding the use of a regular printer for sublimation.

Here, I’ll share some valuable tips to help you achieve the best results.

1. Choose the Right Ink

One of the most crucial aspects of using a regular printer for sublimation is the ink. Regular printers typically use dye-based or pigment-based inks, which are not suitable for sublimation.

Instead, you should:

- Purchase sublimation ink: Look for high-quality sublimation ink specifically designed for your printer model. This ink is essential for the sublimation process, as it converts into gas when heated, allowing it to bond with the substrate.

- Check compatibility: Make sure that the sublimation ink you choose is compatible with your printer brand and model. Using the wrong ink can lead to poor print quality and damage to your printer.

2. Prepare Your Printer

Before you start printing, it’s essential to prepare your printer properly:

- Clean the printhead: Regular maintenance is vital. Run a cleaning cycle on your printer to ensure that the printhead is free of any old ink or debris that could affect print quality.

- Use the right settings: Adjust your printer settings to the highest quality. Set the paper type to “photo” or “fine art” to ensure that the printer uses the best available settings for your sublimation prints.

3. Select the Right Paper

The type of paper you use can significantly impact your sublimation results:

- Use sublimation paper: It’s specifically designed to hold sublimation ink and release it effectively during the heat transfer process. Regular paper won’t provide the same results.

- Consider weight and coating: Choose a paper weight that suits your project. Heavier papers tend to produce better results. Look for papers with a coating that can absorb the ink efficiently.

4. Optimize Your Design

Getting your design right is crucial for successful sublimation:

- Use high-resolution images: Ensure that your designs are in high resolution (300 DPI or higher) to avoid pixelation. This is especially important for larger prints.

- Mirror your images: When printing designs that will be transferred, remember to mirror them in your design software. This step is essential for proper alignment on the final product.

5. Master the Heat Press

The heat press plays a vital role in sublimation printing:

- Choose the right temperature and time: Typically, sublimation requires a temperature of around 385°F (196°C) for 45-60 seconds. However, this can vary based on the material you’re using, so always refer to the manufacturer’s guidelines.

- Use even pressure: Ensure that your heat press applies even pressure across the entire design. Uneven pressure can result in patchy prints.

- Preheat your substrate: Preheating the item you are sublimating can help remove moisture and ensure better ink transfer.

6. Test and Experiment

Since using a regular printer for sublimation is less conventional, don’t hesitate to test different methods:

- Run test prints: Always do a test print before committing to a large project. This allows you to identify any issues with colors, alignment, or settings.

- Experiment with materials: Different substrates can yield different results. Try sublimating on various materials like polyester fabric, mugs, or metal to see what works best for you.

7. Troubleshooting Common Issues

Sometimes things don’t go as planned. Here are some common issues and how to address them:

- Faded colors: If your prints come out faded, check your ink levels and ensure that you are using the correct settings.

- Blurry images: Blurriness can result from low-resolution images or dirty printheads. Make sure to clean your printer regularly and use high-quality images.

- Ghosting: If you notice ghosting (a shadow effect) on your prints, it may be due to improper pressure or heat settings. Adjust these factors for better results.

By following these tips, you can make the most out of your regular printer for sublimation projects.

With a little practice and experimentation, you’ll be able to create stunning sublimation prints that showcase your creativity.

Conclusion

When considering whether to use a regular printer for sublimation, it’s important to weigh your options carefully.

As someone who has navigated this process, I understand the nuances involved. Let’s explore the final thoughts on this topic.

Understanding Your Needs

Before deciding to use a regular printer for sublimation, it’s essential to evaluate your specific needs.

Are you planning to produce high-quality images for personal projects, or are you looking to start a small business?

Knowing your goals will guide your decisions.

Quality of Output

One of the primary considerations is the quality of the output. Regular printers, especially those designed for standard paper printing, may not provide the same level of detail and vibrancy that specialized sublimation printers offer.

Here are some factors to consider:

- Ink Quality: Sublimation inks are formulated to work with heat transfer processes. Regular ink may not yield the same results.

- Color Accuracy: Sublimation printing requires precise color reproduction. A regular printer may not have the necessary calibration for accurate colors.

- Print Resolution: Check the print resolution of your regular printer. Higher resolutions are preferable for detailed images.

Cost Considerations

Using a regular printer for sublimation can be a cost-effective option initially, but there are hidden costs to consider:

- Initial Investment: If you already own a regular printer, it might seem like a good idea to use it for sublimation. However, the costs of sublimation inks and transfer paper can add up.

- Long-Term Costs: Over time, the quality of prints may suffer, leading to the need for a dedicated sublimation printer.

Printer Modifications

If you decide to go ahead with using a regular printer for sublimation, be aware that modifications might be necessary.

Here’s what you might need to do:

- Ink Conversion: Some users opt to convert their printers to accept sublimation inks. This process can be complex and may void warranties.

- Printhead Maintenance: Regular printers may require more frequent maintenance when using sublimation inks, as these inks can clog the printheads.

Compatibility with Sublimation Paper

Choosing the right sublimation paper is crucial. Regular printers may not be compatible with all types of sublimation paper.

Here’s what to keep in mind:

- Paper Thickness: Ensure that your regular printer can handle the thickness of sublimation paper. Some printers may jam with thicker sheets.

- Coated vs. Uncoated: Sublimation paper is usually coated to facilitate ink transfer. Verify that your printer can accommodate this type of paper.

Experimentation and Learning

Using a regular printer for sublimation can be a learning experience. I recommend keeping a few things in mind:

- Start Small: Begin with smaller projects to test the printer’s capabilities. This will help you gauge the quality of prints without significant investment.

- Document Your Process: Keep a record of what works and what doesn’t. This documentation will be invaluable as you refine your technique.

Final Thoughts

Ultimately, while using a regular printer for sublimation can be tempting, it’s essential to weigh the pros and cons.

If you are serious about sublimation printing, investing in a dedicated sublimation printer may save you time, money, and frustration in the long run.

As you navigate this journey, remember that quality is key. Your projects deserve the best, and understanding your tools is vital to achieving that.

If you have any questions or need further guidance, feel free to reach out. I’m here to help you make informed decisions that align with your goals.

FAQs: Can I Use a Regular Printer for Sublimation?

If you’re wondering whether a regular printer can be used for sublimation printing, it’s essential to understand the differences in technology and ink types. Here’s what you need to know.

1. Can I use a regular inkjet printer for sublimation printing?

No, a regular inkjet printer is not suitable for sublimation printing. Sublimation requires specific inks and printer components designed for heat transfer processes.

2. What type of printer do I need for sublimation?

You need a sublimation printer or a converted inkjet printer that is compatible with sublimation ink. Brands like Epson and Sawgrass are popular choices for sublimation printing.

3. Can I convert my regular printer to a sublimation printer?

Yes, you can convert a regular inkjet printer to a sublimation printer by replacing the standard ink with sublimation ink and ensuring the printer is compatible with this process.

4. What is the difference between sublimation ink and regular ink?

Sublimation ink is specifically designed to turn into gas when heated, allowing it to bond with polyester materials. Regular ink does not have this property and will not work for sublimation.

5. Do I need special paper for sublimation printing?

Yes, sublimation printing requires special sublimation paper that can absorb the ink and release it when heat is applied, ensuring vibrant and long-lasting prints.

6. Can I use sublimation ink in a regular printer?

While it is technically possible, using sublimation ink in a regular printer is not recommended. The printer’s components may not be designed for the heat and chemical properties of sublimation ink.

7. Is sublimation printing only for fabric?

No, sublimation printing can be used on various materials, including ceramics, metals, and plastics, as long as they are coated with a polyester finish or are made of polyester.

8. How do I know if my printer is compatible with sublimation ink?

Check the printer’s specifications and documentation. If it is an inkjet printer, ensure it can handle dye-sublimation ink and is compatible with sublimation printing processes.

9. What are the advantages of using a sublimation printer?

Sublimation printers offer vibrant colors, excellent detail, and durability in prints. They are particularly effective for custom apparel and promotional products.

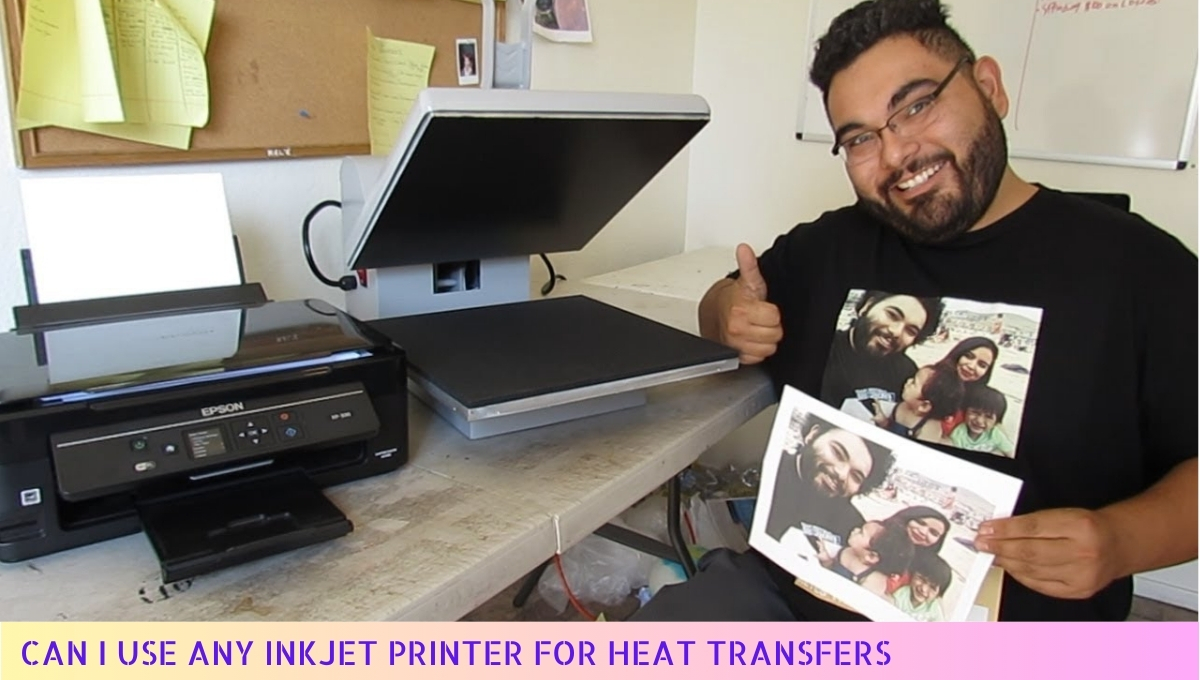

10. Can I use a regular printer for heat transfer instead of sublimation?

Yes, you can use a regular printer for heat transfer printing with the appropriate heat transfer paper. However, the results may not be as vibrant or durable as those from sublimation printing.

Wrap Up

Using a regular printer for sublimation may seem tempting, but it’s essential to understand the limitations and requirements involved.

While it’s possible to convert certain inkjet printers for sublimation, the quality and longevity of the prints can suffer without the right equipment and ink.

Investing in a dedicated sublimation printer ensures vibrant colors and durable results that truly stand the test of time.

I appreciate you taking the time to read through this information.

If you found it helpful, consider sharing it with friends who might also benefit from this knowledge. Your support means a lot!

Feel free to revisit our website for more insights and tips on printing and crafting. Thank you for being part of our community! 🌟