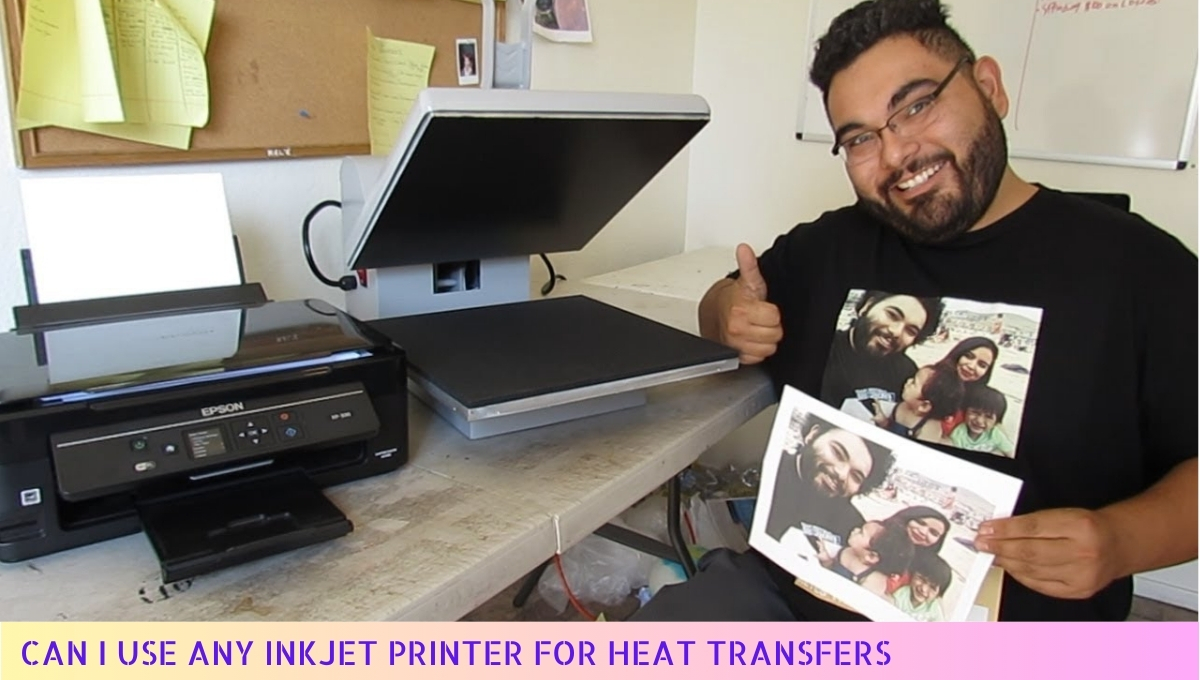

Yes, you can use most inkjet printers for heat transfers, but it’s best to use one that is compatible with transfer paper.

While many inkjet printers can handle heat transfer printing, it’s important to choose one that uses dye-based or pigment-based inks specifically designed for this purpose.

Additionally, ensure you have the right type of transfer paper, as different papers work better with specific printer models. This will help achieve vibrant and durable prints on your fabric.

Factors to Consider Before Using an Inkjet Printer for Heat Transfers

As someone who has explored various printing methods, I understand the importance of choosing the right printer for heat transfers. Below are key factors to consider before investing in an inkjet printer for your projects.

1. Printer Compatibility with Heat Transfer Paper

When selecting an inkjet printer for heat transfers, the first thing to check is whether it is compatible with heat transfer paper. Not all printers are designed to handle this type of media, so you should ensure your chosen model can accommodate it. Here are some points to keep in mind:

- Paper Type: Make sure the printer can handle the specific type of heat transfer paper you plan to use, such as light or dark transfer paper.

- Print Quality: Look for a printer that offers high-resolution printing, as this will affect the clarity and vibrancy of your designs.

- Size Compatibility: Consider the maximum paper size the printer can handle, especially if you plan to print larger designs.

2. Ink Type

The type of ink used in your printer is crucial for achieving optimal results with heat transfers.

Most inkjet printers use dye-based or pigment-based inks, and understanding the differences can help you make an informed choice.

- Dye-Based Inks: These inks typically produce vibrant colors and are suitable for light transfer papers. However, they may not be as durable as pigment-based inks.

- Pigment-Based Inks: These inks offer better durability and are ideal for dark transfer papers. They resist fading and water damage, making them a better choice for long-lasting designs.

3. Print Speed and Volume

If you plan to use your inkjet printer for heat transfers regularly or for larger projects, print speed and volume become important factors.

- Print Speed: Look for a printer that offers a fast print speed, especially if you’ll be printing multiple designs or bulk orders.

- Monthly Duty Cycle: Check the printer’s monthly duty cycle to ensure it can handle your printing needs without wearing out quickly.

4. Cost of Ink and Maintenance

Before making a purchase, it’s essential to consider the long-term costs associated with ink and maintenance.

- Ink Costs: Research the price of replacement ink cartridges for the printer. Some printers may have lower upfront costs but higher ink expenses.

- Maintenance: Look for printers that are easy to maintain and clean, as this can save you time and money in the long run.

5. User Reviews and Recommendations

Before committing to a specific printer, take the time to read user reviews and seek recommendations from others who have experience with heat transfers. This can provide valuable insights into the printer’s performance and reliability.

- Online Reviews: Websites like Amazon and specialized printing forums can offer a wealth of user experiences.

- Community Feedback: Engage with online communities, such as Facebook groups or Reddit threads, to ask for recommendations based on real-world use.

6. Additional Features

Consider any additional features that might enhance your printing experience.

- Wireless Connectivity: A printer with wireless capabilities can simplify the printing process, allowing you to print directly from your computer or mobile device.

- Color Management: Some printers come with advanced color management options that can help you achieve more accurate color reproduction.

7. Warranty and Customer Support

Lastly, don’t overlook the importance of warranty and customer support. A good warranty can provide peace of mind, while responsive customer support can be invaluable if you encounter any issues.

- Warranty Length: Check how long the warranty lasts and what it covers.

- Support Availability: Look for printers from manufacturers known for good customer service and support.

By considering these factors carefully, you can select the right inkjet printer for your heat transfer projects. My aim is to help you make an informed decision that will lead to successful and satisfying results in your printing endeavors.

Recommended Inkjet Printers for Heat Transfers

When it comes to heat transfer printing, choosing the right inkjet printer is crucial. I’ve researched and compiled a list of printers that excel in this specific application, ensuring you achieve the best results possible.

1. Epson EcoTank ET-2720

The Epson EcoTank ET-2720 is a top contender for heat transfer printing. Its refillable ink tank system allows for cost-effective printing, which is ideal for those of you who plan to create multiple designs.

- High Resolution: This printer offers a maximum resolution of 4800 x 1200 dpi, producing sharp and vibrant images.

- Cost-Effective: With the EcoTank system, you save money on ink, making it budget-friendly for small businesses or hobbyists.

- Wireless Printing: The ability to print from your smartphone or tablet adds convenience to your workflow.

2. Canon PIXMA TS8320

If you’re looking for versatility, the Canon PIXMA TS8320 is a great choice. It can handle various media types, making it suitable for both heat transfers and regular printing needs.

- Six-Color Individual Ink System: This printer uses a six-color system, ensuring that your heat transfer prints have rich colors and gradients.

- Print Size Flexibility: It can print on various paper sizes, including larger formats for bigger designs.

- User-Friendly Interface: The touchscreen display makes navigation easy, allowing you to adjust settings quickly.

3. HP Envy 6055

The HP Envy 6055 combines affordability with functionality. It’s perfect for those just starting with heat transfer printing.

- All-in-One Features: This printer offers scanning and copying capabilities, making it a versatile addition to your home office.

- Smart App Connectivity: You can manage your printing tasks from your smartphone, making it convenient to print designs on the go.

- Good Quality Prints: With a maximum resolution of 4800 x 1200 dpi, it produces quality prints suitable for heat transfer.

4. Brother MFC-J995DW

The Brother MFC-J995DW is another excellent choice for heat transfer printing, especially for those who value efficiency.

- INKvestment Tank System: This printer comes with high-yield ink cartridges that can print more pages, reducing the frequency of replacements.

- Automatic Duplex Printing: Save on paper costs with automatic two-sided printing, which is a plus for any printing project.

- Fast Printing Speed: With a speed of up to 12 pages per minute, it’s suitable for those who need to print large volumes quickly.

5. Epson SureColor F170

If you’re serious about heat transfer printing, consider the Epson SureColor F170. This printer is specifically designed for dye-sublimation printing, which is ideal for fabric transfers.

- Professional Quality: With a maximum resolution of 1200 x 1200 dpi, it produces stunningly detailed prints.

- Compact Design: Its small footprint makes it easy to fit into any workspace.

- Wide Color Gamut: This printer provides a broad color spectrum, allowing for vibrant and accurate color reproduction.

6. Canon imagePROGRAF PRO-1000

The Canon imagePROGRAF PRO-1000 is perfect for professionals looking for high-end results. It’s a bit pricier but worth the investment for serious heat transfer projects.

- 12-Color LUCIA PRO Ink System: This advanced ink system provides exceptional color accuracy and depth.

- Large Format Printing: It can handle larger paper sizes, making it ideal for oversized designs.

- Advanced Media Handling: This printer can accommodate various media types, ensuring versatility in your printing options.

Choosing the right printer for heat transfers is essential for achieving the quality and results you desire.

Each of these recommended printers offers unique features that cater to different needs, whether you are a hobbyist or a professional.

Take your time to assess which one aligns best with your requirements, and you’ll be well on your way to creating stunning heat transfer prints.

Tips for Achieving the Best Results with an Inkjet Printer for Heat Transfers

When it comes to heat transfers using an inkjet printer, I’ve learned a few essential tips that can significantly improve the quality of your prints. Below, I’ll share my insights to help you achieve the best results.

1. Choose the Right Transfer Paper

One of the most critical factors in heat transfer printing is selecting the appropriate transfer paper. The type of paper you use can greatly affect the final outcome of your designs. Here are a few considerations:

- Type of Fabric: Ensure that the transfer paper is compatible with the fabric you are using. There are specific papers designed for cotton, polyester, and blends.

- Ink Compatibility: Make sure the transfer paper works well with your inkjet printer’s ink. Some papers are optimized for dye-based inks, while others are better for pigment-based inks.

- Finish: Decide whether you want a matte or glossy finish. This can affect the overall look of your final product.

2. Adjust Your Printer Settings

Before printing, I always take a moment to adjust the printer settings to ensure the best quality output. Here’s what I recommend:

- Print Quality: Set your printer to the highest quality setting available. This will enhance the details and colors of your design.

- Paper Type: Select the appropriate paper type in your printer settings. Most printers allow you to choose between plain paper, photo paper, or specialty paper.

- Color Management: Ensure that your color management settings are correct. This helps in achieving accurate colors in your final print.

3. Test Your Design

Before committing to a final print, I always recommend doing a test print. This can save you time and resources. Here’s how to effectively test your design:

- Scale Down: Print a smaller version of your design to check for any issues in colors, alignment, and detail.

- Use Regular Paper: Test your design on regular paper first to see how it looks before using transfer paper.

- Check for Errors: Look for any mistakes in your design, such as typos or alignment issues, before proceeding to the final print.

4. Properly Prepare the Fabric

The fabric you choose for your heat transfer is just as important as the printing process itself. Here are some preparation tips:

- Pre-Wash: Wash and dry the fabric before applying the transfer. This helps to remove any finishes that may interfere with adhesion.

- Ironing: Iron the fabric to remove wrinkles and ensure a smooth surface for the transfer. This can help the design adhere better.

- Surface Cleanliness: Make sure the fabric is free from dust, lint, and other debris that could affect the transfer quality.

5. Use the Right Heat Press Settings

Using a heat press can make a significant difference in the quality of your heat transfers. Here’s what I’ve found works best:

- Temperature: Follow the transfer paper instructions for the recommended temperature. Too hot can scorch the fabric, while too low can result in poor adhesion.

- Time: Timing is crucial. Ensure you apply heat for the recommended duration to achieve the best results.

- Pressure: Use even pressure across the entire design. This ensures that every part of the transfer adheres properly.

6. Allow for Cooling and Peeling

After pressing, I always let the fabric cool down before peeling off the transfer paper. Here’s why this step is important:

- Adhesion: Allowing the design to cool helps it adhere better to the fabric.

- Peeling Technique: Follow the instructions for peeling, whether it’s warm or cold peel. This can affect the final look of your design.

7. Store Your Transfers Properly

If you’re making multiple heat transfers, proper storage is essential:

- Keep Flat: Store printed transfers flat to avoid creasing or damage.

- Avoid Sunlight: Keep them away from direct sunlight to prevent fading.

- Temperature Control: Store in a cool, dry place to maintain the integrity of the transfers.

By following these tips, you can significantly improve your heat transfer results with an inkjet printer. Remember, practice makes perfect, and each project will teach you something new! Happy printing!

Common Mistakes to Avoid When Using an Inkjet Printer for Heat Transfers

As I explore the world of heat transfers using inkjet printers, I’ve learned that avoiding common pitfalls can significantly enhance your results. Let’s delve into the mistakes that you should steer clear of to achieve the best outcomes.

1. Using the Wrong Type of Ink

One of the most critical factors in heat transfer printing is the type of ink you use. Many people make the mistake of using standard inkjet ink instead of specialized inks designed for heat transfers. Here’s why this matters:

- Quality of Transfer: Standard inks may not adhere well to heat transfer materials, resulting in faded or peeling designs.

- Durability: Specialized inks are formulated to withstand the heat and pressure of the transfer process, ensuring a longer-lasting finish.

Always opt for inkjet inks that are specifically labeled for heat transfer applications to achieve the best results.

2. Not Testing Your Designs

Another common mistake is neglecting to test your designs before committing to a large batch. Here’s why testing is essential:

- Color Accuracy: Colors can appear differently on paper than they do on the final product. Testing helps you adjust the color settings accordingly.

- Material Compatibility: Different materials react differently to heat transfers. Testing ensures that your design adheres properly to the intended surface.

Always run a few test prints on the actual material you plan to use. This simple step can save you time and resources.

3. Ignoring Printer Settings

Your printer settings play a crucial role in the quality of your heat transfers. Many users make the mistake of sticking to default settings. Here’s what you should do instead:

- Paper Type: Ensure that you select the correct paper type in your printer settings. Using the wrong setting can affect ink distribution.

- Print Quality: Always set your printer to the highest quality setting when printing heat transfer designs. This ensures better detail and color saturation.

Take the time to adjust your printer settings for each project to achieve optimal results.

4. Overlooking the Importance of Heat Pressing

After printing, many people underestimate the significance of the heat pressing process. Here are some common mistakes to avoid:

- Temperature and Time: Not following the recommended temperature and pressing time can lead to poor adhesion. Always refer to the instructions that come with your heat transfer materials.

- Pressure: Applying insufficient or excessive pressure can affect the quality of the transfer. Make sure you use the right amount of pressure as specified by the manufacturer.

Investing in a reliable heat press machine and understanding how to use it properly can make a significant difference in your results.

5. Neglecting Post-Transfer Care

Once your heat transfer is complete, the care you provide is essential for longevity. Many people overlook post-transfer care, leading to premature wear. Here are key tips:

- Washing Instructions: Always follow washing instructions for heat transfer materials. Typically, it’s best to wash in cold water and avoid harsh detergents.

- Avoiding Direct Heat: Do not iron directly over the transferred design. Instead, use a protective sheet to avoid damaging the transfer.

Taking care of your heat transfers will help them last longer and maintain their appearance.

6. Skipping the Cleaning Process

Another mistake that can compromise your heat transfer quality is neglecting to clean your printer regularly. Here’s why cleaning is vital:

- Preventing Clogs: Inkjet printers can develop clogs if not maintained properly. Regular cleaning prevents issues that can lead to poor print quality.

- Color Consistency: A clean printer ensures that colors remain consistent and vibrant, which is essential for heat transfer projects.

Make it a habit to clean your printer according to the manufacturer’s guidelines to keep it in top condition.

7. Failing to Plan Your Layout

Lastly, many users overlook the importance of planning their design layout. Here’s what to consider:

- Space Management: Ensure that your design fits well on the transfer material. Poor layout can lead to wasted materials.

- Alignment: Always check that your design is aligned correctly with your heat transfer material. Misalignment can ruin the overall look.

By taking the time to plan your layout, you’ll save both time and materials while achieving a professional finish.

FAQs: Can I Use Any Inkjet Printer for Heat Transfers?

Using an inkjet printer for heat transfers is a common practice, but not all printers are suitable. Understanding the specifics can help you achieve the best results for your projects.

1. Can any inkjet printer be used for heat transfer printing?

No, not all inkjet printers are suitable for heat transfer printing. Printers that use dye-based inks may not provide the best results. It’s recommended to use printers that are compatible with pigment-based inks for better durability and color vibrancy.

2. What type of ink is best for heat transfer printing?

Pigment-based inks are generally preferred for heat transfer printing because they adhere better to transfer paper and provide longer-lasting results. Dye-based inks can fade more quickly and may not withstand washing as well.

3. Do I need special paper for heat transfers?

Yes, using special heat transfer paper is essential. There are different types of transfer paper designed for light and dark fabrics, and using the correct one will significantly affect the quality of your prints.

4. Can I use my regular inkjet printer for fabric transfers?

While you can use a regular inkjet printer, it is important to ensure that it is compatible with pigment-based inks and the appropriate heat transfer paper for optimal results on fabric.

5. What settings should I use on my printer for heat transfers?

When printing for heat transfers, set your printer to the highest quality setting. Additionally, you may need to adjust the paper type setting to match the transfer paper you are using.

6. Will heat transfer printing damage my printer?

Generally, heat transfer printing should not damage your printer if you use compatible inks and papers. However, using low-quality materials can lead to clogs or damage over time.

7. How do I ensure the best results with heat transfer printing?

To achieve the best results, use high-quality heat transfer paper, ensure your printer settings are optimized, and follow the heat transfer process carefully, including proper temperature and pressure settings.

8. Can I use a color printer for heat transfers?

Yes, color inkjet printers can be used for heat transfers. Just make sure that the inks used are suitable for the type of transfer paper you choose, especially if you’re working with fabrics.

9. How long do heat transfer prints last?

With proper care, heat transfer prints can last several washes. Using pigment-based inks and high-quality transfer paper will enhance the longevity of the prints.

10. Is it necessary to have a specific brand of printer for heat transfers?

No specific brand is required for heat transfer printing. However, researching and choosing a printer known for quality ink and print durability will yield better results.

Wrap Up

When it comes to using an inkjet printer for heat transfers, it’s essential to understand that not all printers are created equal.

I’ve learned that using the right type of ink, specifically pigment-based or dye-sublimation inks, can make a significant difference in the quality of your prints.

Ensuring compatibility with transfer paper is also crucial to achieve vibrant and lasting results.

Choosing the right printer for your heat transfer projects can save you time and frustration. Investing in a printer designed for this purpose can enhance your creativity and lead to impressive outcomes.

I encourage you to do thorough research and select a model that aligns with your needs.

Thank you for taking the time to read this article! If you found the information helpful, please share it with friends and revisit our site for more insights. Your support means a lot! 😊