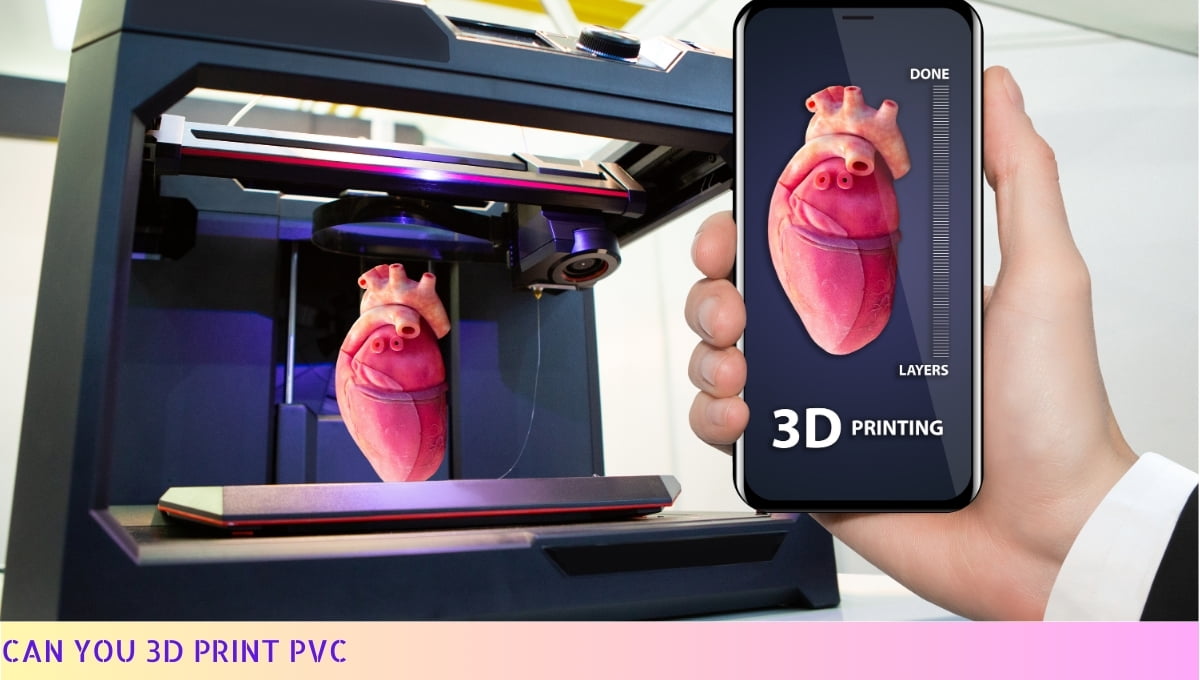

Yes, you can 3D print PVC.

Polyvinyl chloride (PVC) is a widely used thermoplastic that can be melted and extruded through a 3D printer nozzle to create three-dimensional objects.

However, it is important to note that PVC emits toxic fumes when heated, so proper ventilation and safety precautions should be taken when 3D printing with this material.

I. Benefits of 3D Printing PVC

When it comes to 3D printing, PVC (Polyvinyl Chloride) offers a plethora of benefits that make it a popular choice among creators and manufacturers. Let me tell you, it’s like hitting the jackpot in the world of 3D printing!

First and foremost, PVC is known for its versatility. It can be molded into various shapes and sizes, allowing you to bring your wildest imagination to life. Whether you’re creating intricate designs or functional prototypes, PVC has got your back.

Not only that, but PVC is also lightweight and durable, making it perfect for a wide range of applications. You can print objects that are strong and sturdy, without adding unnecessary weight. It’s like having your cake and eating it too!

Now, let’s talk about the cost-effectiveness of 3D printing PVC. Trust me, it’s a game-changer!

PVC is an affordable material, and when combined with the cost-saving benefits of 3D printing, you’ll be saving some serious dough. Who doesn’t love that?

And here’s the cherry on top: PVC is resistant to moisture, chemicals, and UV rays.

This means that your 3D printed PVC creations will stand the test of time, whether they’re exposed to the elements or used in demanding environments. It’s like having a superhero material at your disposal!

So, if you’re looking for a material that offers versatility, durability, cost-effectiveness, and resistance to the elements, PVC is the way to go.

With 3D printing, the possibilities are endless, and PVC is here to take your creations to the next level. Trust me, you won’t be disappointed!

II. Challenges of 3D Printing PVC

1. Material Limitations

When it comes to 3D printing PVC, there are some challenges you need to be aware of. One of the main hurdles is the limitations of the material itself. PVC, or polyvinyl chloride, can be a bit stubborn to work with.

It has a high melting point, which means you need to carefully control the temperature during the printing process. If the temperature is too low, the material won’t flow properly, resulting in weak and brittle prints.

On the other hand, if the temperature is too high, it can lead to warping and deformation of the printed object.

2. Toxic Fumes

Another challenge with 3D printing PVC is the emission of toxic fumes. PVC contains chlorine, and when heated, it releases harmful gases such as hydrogen chloride.

These fumes can be dangerous if inhaled, so it’s essential to have proper ventilation in your workspace. Make sure to use a well-ventilated area or consider using a fume extraction system to minimize the risk.

3. Print Bed Adhesion

Getting good adhesion between the print bed and the PVC material can be a bit tricky. PVC has a tendency to warp and detach from the print bed during the printing process.

To overcome this challenge, it’s crucial to properly prepare the print bed surface and use effective adhesion methods. Applying a layer of adhesive such as glue stick or using a heated bed can help improve bed adhesion and prevent warping.

4. Post-Processing and Finishing

Once you’ve successfully printed your PVC object, you may encounter challenges in post-processing and finishing. PVC has a smooth surface finish, which can make it difficult to paint or add other finishes.

The material is also prone to scratches and marks, so extra care is needed when handling and finishing the printed objects.

Sanding, priming, and using appropriate paints and coatings can help achieve a more polished and durable final product.

5. Limited Availability of PVC Filament

Compared to other commonly used 3D printing materials, such as PLA or ABS, PVC filament is less widely available. Finding a reliable source for PVC filament can be a challenge, and it may come at a higher cost.

However, with the growing popularity of 3D printing, the availability of PVC filament is gradually increasing.

Verdict

Despite the challenges involved, 3D printing PVC offers numerous benefits and exciting possibilities. By understanding and addressing these challenges, you can unlock the potential of PVC as a versatile material for your 3D printing projects.

II. Tips for 3D Printing PVC

1. Choose the Right PVC Filament

When it comes to 3D printing PVC, selecting the right filament is key. Look for a high-quality PVC filament that is specifically designed for 3D printing. Make sure it is compatible with your 3D printer and has good reviews from other users.

Opt for a filament that offers good adhesion, minimal warping, and consistent extrusion.

2. Adjust the Print Settings

To achieve optimal results when printing with PVC, it’s important to fine-tune your print settings. Experiment with different temperatures, layer heights, and print speeds to find the sweet spot for your specific project.

Keep in mind that PVC requires higher temperatures compared to other filaments, so adjust accordingly. Additionally, consider using a heated bed to prevent warping.

3. Ensure Proper Ventilation

PVC can release potentially harmful fumes when heated, so it’s crucial to work in a well-ventilated area.

Make sure your workspace has adequate ventilation or consider using a fume hood or air purifier to minimize any potential health risks. Your safety should always be a top priority when working with PVC or any other filament.

4. Use Support Structures

Due to its tendency to warp, PVC may require the use of support structures during the printing process. Utilize support structures to provide stability and prevent deformation of your prints.

Experiment with different support settings and orientations to achieve the best results. Remember to remove the supports carefully after printing to avoid damaging your final product.

5. Post-Processing Considerations

Once your PVC print is complete, you may need to perform some post-processing to achieve the desired finish. Sanding, polishing, or applying a coating can help smooth out any imperfections and enhance the overall appearance of your print.

Consider using sandpaper, a polishing compound, or a specialized PVC coating to achieve the desired results. Take your time and be patient with the post-processing stage to achieve the best outcome.

6. Learn from Others

Don’t be afraid to seek guidance and learn from the experiences of other 3D printing enthusiasts. Join online communities, forums, or social media groups where you can connect with fellow makers who have experience with printing PVC.

Ask questions, share your own experiences, and gather valuable insights to improve your PVC printing skills. Learning from others can help you avoid common pitfalls and discover new techniques.

7. Practice, Practice, Practice

As with any skill, practice makes perfect. Don’t be discouraged if your initial PVC prints don’t turn out exactly as expected. Embrace the learning process, keep experimenting, and refine your techniques.

With time and practice, you’ll become more proficient in 3D printing PVC and achieve outstanding results.

Summary

When it comes to 3D printing PVC, choosing the right filament, adjusting print settings, ensuring proper ventilation, using support structures, considering post-processing, learning from others, and practicing regularly are key factors for success.

By following these tips, you’ll be well on your way to creating impressive 3D printed objects using PVC filament.

IV. Applications of 3D Printed PVC

Unleashing Creativity

If you’re a creative soul looking to bring your wildest ideas to life, 3D printed PVC is your ticket to boundless possibilities.

With this versatile material, you can let your imagination run wild and create intricate designs that were once unimaginable.

Whether you’re an artist, designer, or hobbyist, 3D printed PVC allows you to push the boundaries of what’s possible.

Prototyping and Product Development

In the fast-paced world of product development, time is money. That’s where 3D printed PVC comes to the rescue. It enables rapid prototyping, allowing you to turn your ideas into tangible models in a jiffy.

With its durability and flexibility, PVC is an ideal choice for creating functional prototypes that closely resemble the final product. It gives you the opportunity to test and refine your designs, saving you time and resources in the long run.

Customized Manufacturing

Gone are the days of one-size-fits-all manufacturing. With 3D printed PVC, you can cater to the unique needs and preferences of your customers.

From personalized accessories to tailor-made components, PVC offers the flexibility to create custom products that stand out from the crowd.

Embrace the power of customization and leave a lasting impression on your customers with 3D printed PVC.

Architectural Models and Scale Replicas

Attention, architects and model enthusiasts! 3D printed PVC opens up a whole new world of possibilities when it comes to creating architectural models and scale replicas.Whether you’re visualizing a new building, recreating a historical

landmark, or showcasing your design concepts, PVC can bring your visions to life with precision and detail. Its lightweight nature makes it easy to handle, while its durability ensures your creations will withstand the test of time.

Educational Tools

Learning doesn’t have to be boring, folks! With 3D printed PVC, educators can revolutionize the way students engage with complex concepts.

From biology models to historical artifacts, PVC allows for the creation of interactive and visually appealing educational tools. Students can get hands-on experience, exploring and understanding subjects in a whole new dimension.

Say goodbye to dull textbooks and hello to immersive learning experiences!

Functional Parts and Components

When it comes to functional parts and components, PVC is a reliable choice. Its strength, durability, and resistance to wear and tear make it suitable for a wide range of applications.

Whether you need gears, casings, or brackets, 3D printed PVC can deliver robust and reliable solutions. So, if you’re in the business of manufacturing or repairing, PVC is your go-to material for creating parts that get the job done.

Summary

In a nutshell, the applications of 3D printed PVC are as vast as your imagination. From unleashing creativity to revolutionizing product development, this versatile material has the power to transform industries and open up new avenues for innovation.

So, if you’re ready to take your projects to the next level, embrace the wonders of 3D printed PVC and let your ideas come to life in ways you never thought possible.

Can You 3d Print Pvc – FAQs

1. Can you 3D print PVC?

Yes, it is possible to 3D print with PVC (Polyvinyl Chloride) material.

2. What is PVC?

PVC is a type of plastic that is commonly used in various applications, including pipes, electrical cables, and construction materials.

3. Is PVC suitable for 3D printing?

Yes, PVC can be used for 3D printing, but it requires a specialized 3D printer that is capable of handling this material.

4. What are the advantages of 3D printing with PVC?

Some advantages of 3D printing with PVC include its durability, flexibility, and resistance to impact and chemicals.

5. Are there any limitations to 3D printing with PVC?

One limitation of 3D printing with PVC is that it can release toxic fumes when heated, so proper ventilation is necessary. Additionally, PVC may not be suitable for intricate or highly detailed designs.

6. Can PVC prints be painted or post-processed?

Yes, PVC prints can be painted or post-processed using various methods, such as sanding, priming, and applying coatings or finishes.

7. Where can I find PVC filament for 3D printing?

PVC filament for 3D printing can be found in various online stores that specialize in 3D printing supplies. It is important to ensure that the filament is specifically designed for 3D printing.

8. What are some common applications of 3D printed PVC?

3D printed PVC can be used in a wide range of applications, including prototyping, manufacturing of custom parts, architectural models, and functional objects.

9. What precautions should I take when 3D printing with PVC?

When 3D printing with PVC, it is important to have proper ventilation in the printing area to avoid inhaling toxic fumes. It is also recommended to use a printer with a heated bed and ensure that the printing temperature is within the specified range for PVC.

10. Can PVC be recycled after 3D printing?

Yes, PVC can be recycled after 3D printing. However, it is important to check local recycling facilities or programs to ensure that PVC is accepted and properly recycled in your area.

Wrapping Up

Alright, folks, we’ve reached the end of our 3D printing journey! So, can you 3D print PVC? Well, the answer is a resounding yes! PVC, also known as polyvinyl chloride, can indeed be 3D printed.

With the right equipment and materials, you can bring your PVC creations to life in the third dimension. Just remember to take the necessary safety precautions and ensure proper ventilation when working with PVC.

So, get those creative gears turning and let your imagination run wild with PVC 3D printing possibilities! Happy printing, my fellow makers!