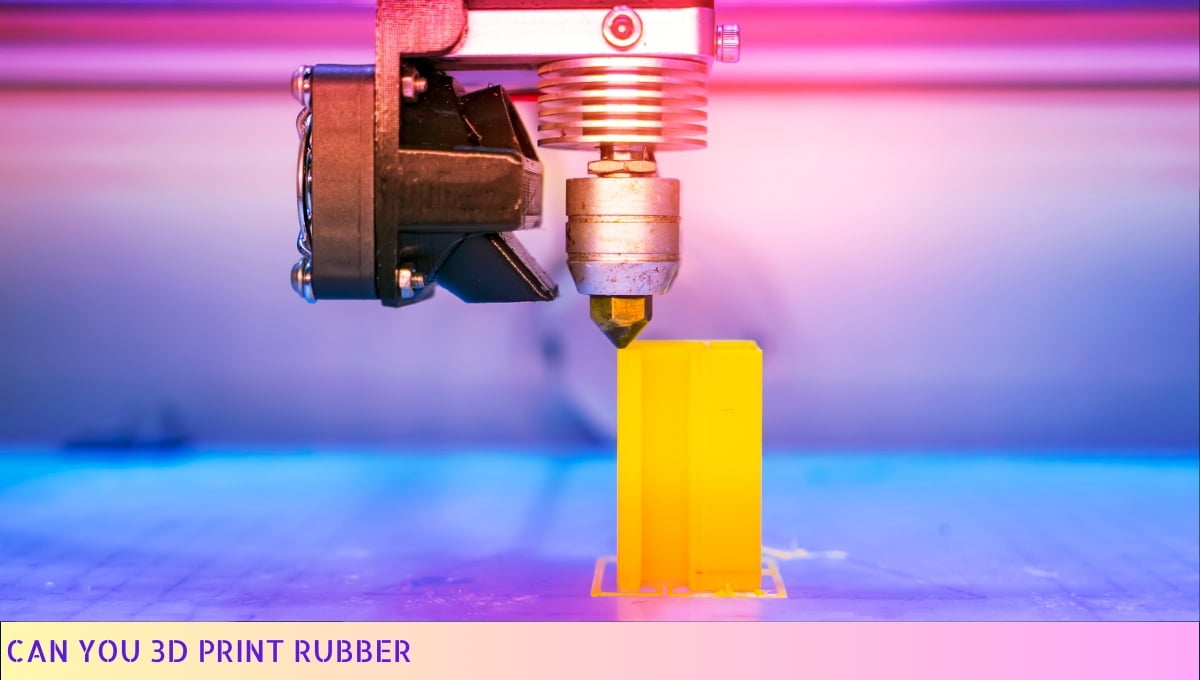

Yes, you can 3D print rubber.

Rubber-like materials, such as thermoplastic elastomers (TPE), can be used in 3D printing to create flexible and durable objects with properties similar to rubber.

The process involves using a specialized 3D printer and filament that is capable of extruding and curing rubber-like materials layer by layer, resulting in the desired shape and texture.

This technology opens up possibilities for creating custom-made rubber products, prototypes, and even wearable items with intricate designs.

I. Advancements in 3D Printing Technology

Let’s talk about the incredible advancements in 3D printing technology. This cutting-edge field has come a long way, revolutionizing various industries and pushing the boundaries of what we thought was possible.

Now, you might be wondering, what exactly is 3D printing? Well, it’s a process where objects are created by layering material on top of each other, following a digital design. Think of it like building something layer by layer, almost like magic!

But here’s the thing, 3D printing hasn’t always been a walk in the park. It faced its fair share of challenges, especially when it came to printing certain materials like rubber.

Now, you might be thinking, can you really 3D print rubber? The answer is a resounding yes! Thanks to recent advancements, it’s now possible to create objects with rubber-like properties using 3D printing technology.

However, let me tell you, it’s not all smooth sailing. There are still some hurdles to overcome when it comes to 3D printing rubber. One of the main challenges is finding the right balance between flexibility and durability.

You see, rubber is known for its stretchiness, but it also needs to be strong enough to withstand everyday use.

Another challenge lies in the printing process itself. Rubber is a tricky material to work with because it tends to be sticky and can easily deform.

So, engineers and scientists are constantly working on developing new techniques and materials to ensure successful 3D printing of rubber.

Now, let’s talk about the exciting applications of 3D printed rubber. This technology opens up a world of possibilities, from creating custom-made shoes with the perfect fit to manufacturing complex rubber seals for industrial machinery.

Imagine being able to design and print your own rubber products, tailored to your specific needs. Whether it’s a prosthetic limb, a personalized phone case, or even a bouncy rubber ball, the possibilities are endless.

The advancements in 3D printing technology have paved the way for the printing of rubber-like materials. While there are challenges to overcome, the potential applications of 3D printed rubber are vast and exciting.

So, keep an eye out for the future of 3D printing, because it’s bound to blow your mind!

II. The Possibility of 3D Printing Rubber

Rubber is a versatile material that is widely used in various industries, from automotive to healthcare. With the advancements in 3D printing technology, there has been a growing interest in the possibility of 3D printing rubber.

In this article, I will explore the potential of this innovative application and discuss the challenges that need to be overcome.

1. Understanding Rubber 3D Printing

Rubber 3D printing, also known as elastomeric additive manufacturing, involves the creation of objects using rubber-like materials.

Unlike traditional manufacturing methods, which often involve molds and casting, 3D printing allows for the direct fabrication of complex rubber structures.

2. Benefits of Rubber 3D Printing

The ability to 3D print rubber opens up a world of possibilities. One major advantage is the freedom to create intricate designs and geometries that would be difficult or impossible to achieve with conventional methods.

This means that engineers and designers can unleash their creativity and push the boundaries of what is possible.

3. Applications of Rubber 3D Printing

Rubber 3D printing has a wide range of potential applications. In the automotive industry, it can be used to create customized gaskets, seals, and flexible components, improving efficiency and reducing costs.

In healthcare, it can enable the production of personalized prosthetics, orthotics, and soft robotics. Additionally, the fashion and sports industries can benefit from the ability to produce unique and comfortable products.

4. Challenges to Overcome

While the possibilities of rubber 3D printing are exciting, there are several challenges that need to be addressed.

One of the main hurdles is the development of rubber-like materials that exhibit the desired mechanical properties, such as flexibility, elasticity, and durability. Researchers are actively working on formulating new materials that can meet these requirements.

5. Printing Process and Parameters

Another challenge lies in optimizing the printing process and parameters for rubber materials.

Factors such as layer adhesion, print speed, and temperature control need to be carefully calibrated to ensure the production of high-quality rubber objects. This requires extensive research and experimentation.

6. Post-Processing and Finishing

Post-processing and finishing techniques for rubber 3D printed objects are also areas that require attention.

As rubber is a flexible material, removing support structures and achieving a smooth surface finish can be more challenging compared to rigid materials. Developing effective post-processing methods will be crucial for achieving the desired final product.

Summary

The possibility of 3D printing rubber holds great promise for various industries. The ability to create complex and customized rubber objects opens up new opportunities for innovation and efficiency.

While there are challenges to overcome, ongoing research and development are paving the way for the widespread adoption of rubber 3D printing. So, get ready to witness a revolution in the way rubber products are made!

III. Challenges in 3D Printing Rubber

1. Material Properties

One of the main challenges in 3D printing rubber lies in the unique properties of the material itself. Rubber is known for its elasticity, flexibility, and resilience, which makes it a versatile material for various applications. However, these very characteristics can pose difficulties in the 3D printing process.

Unlike rigid materials such as plastic or metal, rubber has a tendency to deform or lose its shape during the printing process.

Its high viscosity and low melting point require careful control of temperature and pressure to ensure successful printing. Optimizing the printing parameters becomes crucial to achieve the desired level of accuracy and structural integrity.

2. Printability

Another challenge is the printability of rubber itself. Traditional 3D printers are primarily designed for rigid materials, making it difficult to adapt them for printing with rubber.

The soft and flexible nature of rubber can lead to issues such as warping, curling, or layer misalignment.

Developing specialized printing techniques and equipment that can handle the unique properties of rubber is essential to overcome these challenges.

Advanced printer technologies like direct ink writing (DIW) or selective laser sintering (SLS) have shown promise in improving the printability of rubber.

3. Material Compatibility

When it comes to 3D printing with rubber, another challenge lies in finding compatible materials for support structures or multi-material printing.

Rubber’s adhesion properties differ significantly from other materials, making it challenging to find suitable support materials that can be easily removed or dissolved after printing.

Furthermore, the compatibility of different rubber materials with each other is also a concern. Ensuring proper bonding and adhesion between layers of rubber during the printing process is crucial for achieving the desired mechanical properties in the final printed object.

4. Post-Processing

After the printing process, post-processing steps are often required to achieve the desired characteristics of the printed rubber objects. Depending on the application, these post-processing steps may include curing, vulcanization, or surface treatment.

However, post-processing rubber objects can be challenging due to their unique properties. The curing or vulcanization process requires careful control of temperature, pressure, and time to achieve the desired level of elasticity and strength. Surface treatments such as coating or texturing may also require specialized techniques to ensure proper adhesion and durability.

Summary

Overcoming the challenges in 3D printing rubber is crucial to unlock its full potential in various industries.

With ongoing advancements in materials, printing techniques, and post-processing methods, we can expect to see further improvements in the printability, accuracy, and functionality of 3D printed rubber objects.

By addressing these challenges head-on, we can pave the way for exciting new applications and possibilities in the field of rubber manufacturing.

IV. Applications of 3D Printed Rubber

1. Unleashing Creativity with Customizable Designs

When it comes to 3D printing, the possibilities are virtually endless, especially when it comes to rubber. With this cutting-edge technology, you can unleash your creativity and bring your wildest ideas to life.

Whether you want to create unique fashion accessories, intricate jewelry, or even personalized phone cases, 3D printed rubber allows you to design and customize objects like never before.

2. Revolutionizing the Manufacturing Industry

The advent of 3D printing has brought about a revolution in the manufacturing industry, and rubber is no exception. With traditional manufacturing methods, producing complex rubber components can be time-consuming and costly.

However, with 3D printing, manufacturers can streamline the production process and reduce lead times significantly.

This technology enables the creation of intricate rubber parts with high precision, helping businesses meet the demands of their customers more efficiently.

3. Advancing Medical Applications

The medical field has also embraced the potential of 3D printed rubber. From prosthetics to orthotics, this innovative technology has opened up new avenues for creating custom-fit medical devices.

3D printed rubber prosthetics, for example, offer a more comfortable and natural feel compared to their traditional counterparts. Moreover, this technology allows for the production of patient-specific implants, ensuring a better fit and improved patient outcomes.

4. Enhancing Automotive Performance

In the automotive industry, 3D printed rubber components are making waves. Rubber parts, such as gaskets, seals, and tires, play a crucial role in vehicle performance and safety.

With 3D printing, these components can be customized to meet specific requirements, enhancing performance and reducing the risk of failure.

Additionally, the ability to rapidly prototype and test different designs allows for faster innovation and optimization in the automotive sector.

5. Pushing the Boundaries of Architecture and Design

Architects and designers are pushing the boundaries of their creative endeavors with 3D printed rubber. This technology enables the construction of intricate and unconventional structures that were once deemed impossible.

From flexible facades to resilient building materials, 3D printed rubber offers architects and designers the freedom to explore innovative designs and materials, revolutionizing the way we perceive and interact with our built environment.

6. Exploring New Frontiers in Sports

The sports industry is not one to be left behind when it comes to embracing new technologies. 3D printed rubber is finding its way into sports equipment, providing athletes with enhanced performance and protection.

Customized mouthguards, padding, and shoe soles are just a few examples of how this technology is revolutionizing sports gear.

By tailoring the properties of the rubber to meet specific requirements, athletes can achieve optimal performance while minimizing the risk of injury.

Verdict

The applications of 3D printed rubber are vast and diverse. From unleashing creativity to revolutionizing manufacturing, advancing medical practices, enhancing automotive performance, pushing the boundaries of architecture and design, and exploring new frontiers in sports, this technology is transforming various industries.

As 3D printing technology continues to evolve, we can expect even more exciting and groundbreaking applications for rubber in the future. So, strap on your imagination and get ready to embrace the limitless possibilities of 3D printed rubber!

Can You 3d Print Rubber – FAQs

1. Can you 3D print rubber?

Yes, it is possible to 3D print rubber using certain types of 3D printers and specific rubber-like materials. This technology allows for the creation of flexible and elastic objects.

2. What type of 3D printers can print rubber?

There are various types of 3D printers that can print rubber, including those that use the Fused Deposition Modeling (FDM) or Selective Laser Sintering (SLS) technology. These printers are specifically designed to handle rubber-like materials.

3. What materials are used for 3D printing rubber?

Common materials used for 3D printing rubber-like objects include thermoplastic polyurethane (TPU), thermoplastic elastomer (TPE), and flexible filaments. These materials offer the necessary flexibility and elasticity required for rubber-like properties.

4. Can I print objects with different levels of hardness?

Yes, with the right 3D printer and materials, you can print objects with different levels of hardness. By adjusting the infill density or using different rubber-like materials, you can achieve varying levels of hardness for your 3D printed objects.

5. What are the applications of 3D printed rubber?

3D printed rubber has a wide range of applications, including prototyping, product design, footwear, automotive parts, medical devices, and even fashion accessories. Its flexibility and durability make it suitable for various industries.

6. Is 3D printed rubber as durable as traditionally manufactured rubber?

While 3D printed rubber can offer similar durability to traditionally manufactured rubber, it may not be as strong in all cases. The quality and strength of the 3D printed rubber depend on factors such as the printer settings, material quality, and design.

7. Can I print complex shapes with rubber?

Yes, one of the advantages of 3D printing rubber is the ability to create complex shapes and intricate designs. The flexibility of the material allows for the production of objects with intricate details that may be difficult or impossible to achieve with traditional manufacturing methods.

8. Are there any limitations to 3D printing rubber?

While 3D printing rubber has its advantages, there are some limitations to consider. For example, the printing process can be slower compared to other materials, and the final result may have slightly different properties than traditionally manufactured rubber.

9. Can I use any 3D modeling software to design objects for 3D printing rubber?

Yes, you can use various 3D modeling software programs to design objects for 3D printing rubber. Popular software options include Autodesk Fusion 360, SolidWorks, Tinkercad, and Blender. Make sure to choose a software that is compatible with your 3D printer.

10. Where can I find rubber-like 3D printing materials?

Rubber-like 3D printing materials can be found from various suppliers and online marketplaces that specialize in 3D printing supplies. Some popular brands offering rubber-like filaments include NinjaTek, FormFutura, and FilamentOne.

Wrapping Up

Well folks, we’ve reached the end of our 3D printing adventure. Can you 3D print rubber? The answer is a resounding yes! With the right materials and techniques, you can bring your rubbery dreams to life.

Whether it’s creating custom gaskets, soft touch prototypes, or even flexible phone cases, 3D printing has got you covered. So, don’t let the limitations of traditional manufacturing hold you back.

Embrace the world of 3D printing and let your imagination run wild. It’s time to bring some bounce to your creations!