The revolutionary history of 3D printing began with the invention of stereolithography in the early 1980s by Charles W.

Hull, which paved the way for the development of additive manufacturing technologies that have transformed various industries.

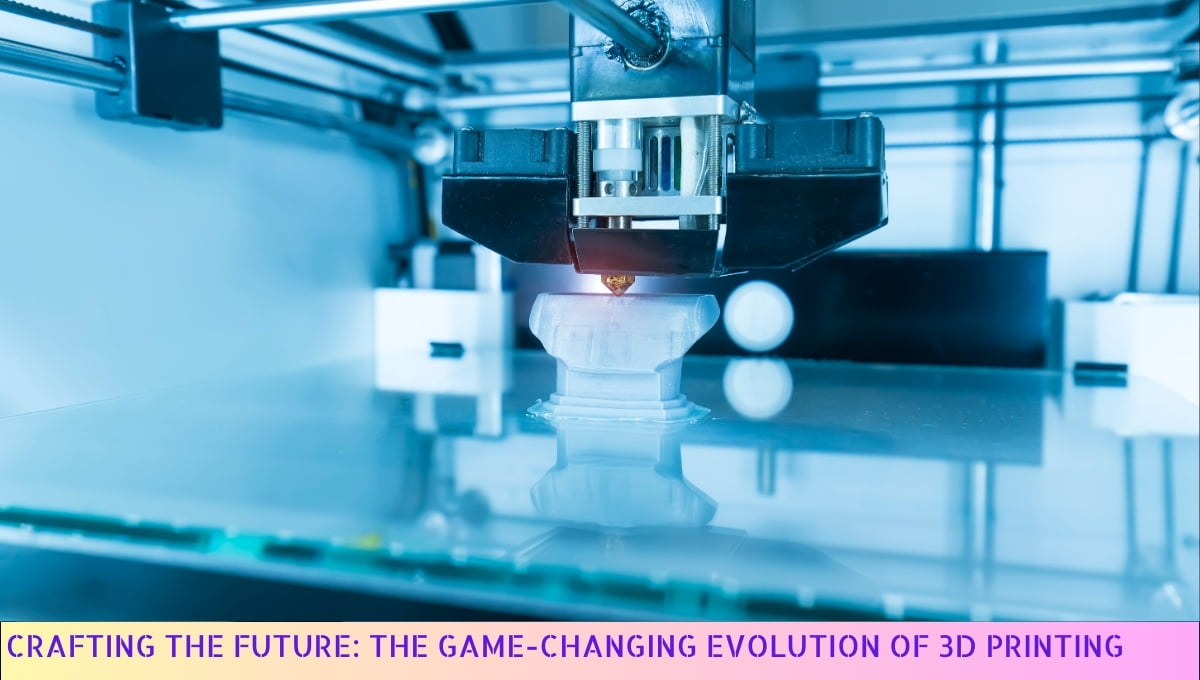

3D printing, also known as additive manufacturing, is a process that creates three-dimensional objects by layering materials such as plastics, metals, or ceramics.

The concept of 3D printing has been around since the 1970s, but it was Hull who introduced the first commercial 3D printing technology.

His invention, stereolithography, used a UV laser to solidify liquid resin layer by layer, leading to the creation of solid objects.

I. The Origins of 3D Printing

Hey there! Let’s dive into the fascinating world of 3D printing, shall we? Buckle up, because we’re about to embark on a journey through time and innovation.

Back in the day, when dinosaurs roamed the earth (just kidding, it was the 1980s), a group of ingenious minds came up with the concept of 3D printing.

It was like something out of a sci-fi movie, where objects could be created layer by layer, right before your very eyes. Talk about mind-blowing!

Now, you might be wondering, who were these masterminds? Well, my friend, it was a team of scientists and engineers who paved the way for this groundbreaking technology.

Chuck Hull, a true hero in the 3D printing realm, invented the first-ever 3D printer. Can we get a round of applause for Chuck?

Advancements and Innovations in 3D Printing Technology

Fast forward to today, and 3D printing has come a long way, baby! The advancements in this field are nothing short of remarkable. With each passing day, we witness new innovations that push the boundaries of what’s possible.

Nowadays, 3D printers aren’t just limited to printing plastic trinkets. Oh no, they can do so much more! We’re talking about printing metal parts, human organs (yes, you heard that right), and even food.

Imagine printing a pizza, hot and fresh, straight from the printer. It’s a brave new world, my friend.

Applications and Impact of 3D Printing in Various Industries

Hold on tight, because we’re about to explore the mind-boggling applications of 3D printing across different industries. From healthcare to aerospace, this technology has left its mark everywhere.

In the medical field, 3D printing has revolutionized the way we approach healthcare. Doctors can now create customized implants and prosthetics, tailored specifically to a patient’s needs.

It’s like having a personal tailor for your body. How cool is that?

But wait, there’s more! In the world of fashion, designers are using 3D printers to bring their wildest dreams to life.

They can create intricate jewelry, avant-garde garments, and accessories that would make Lady Gaga jealous. It’s a fashionista’s dream come true.

Future Prospects and Challenges in 3D Printing

As with any emerging technology, 3D printing has its fair share of challenges and hurdles to overcome. But fear not, my friend, for the future looks bright and promising.

One of the biggest challenges we face is the cost of 3D printers and materials. As with any new technology, the initial investment can be quite hefty.

However, as the technology continues to evolve, we can expect prices to become more affordable, making it accessible to a wider audience.

Another challenge lies in the regulatory landscape. As 3D printing becomes more widespread, there will be a need for regulations to ensure safety and quality standards are met.

It’s all about finding the right balance between innovation and accountability.

3D printing has come a long way since its humble beginnings. It has the potential to revolutionize industries, change lives, and unlock endless possibilities.

So, my friend, keep your eyes peeled for what the future holds, because the world of 3D printing is just getting started. Happy printing!

II. Advancements and Innovations in 3D Printing Technology

Over the years, 3D printing technology has witnessed remarkable advancements and innovations, revolutionizing various industries.

From its humble beginnings as a niche manufacturing process, it has evolved into a powerful tool with endless possibilities.

Here, I will explore some of the key advancements and innovations that have shaped the field of 3D printing.

1. Improved Printing Materials

One of the major advancements in 3D printing technology is the development of a wide range of high-quality printing materials.

Initially, 3D printers were limited to using plastic filaments, but now, there are options such as metal, ceramics, and even bio-compatible materials.

These advancements have expanded the scope of applications for 3D printing, enabling the production of complex and functional objects with enhanced durability and performance.

2. Faster and More Precise Printing

Another significant advancement in 3D printing is the improvement in printing speed and precision. Early 3D printers were relatively slow and had limited accuracy, making them unsuitable for large-scale production.

However, with the introduction of advanced printing technologies like stereolithography and selective laser sintering, printers can now create intricate designs with micron-level precision at a much faster rate.

This has opened up new possibilities for rapid prototyping and on-demand manufacturing.

3. Multi-Material and Multi-Color Printing

The ability to print with multiple materials and colors has been a game-changer in the world of 3D printing. Earlier, 3D printers could only print objects in a single material and color, limiting their versatility.

However, with advancements in printing technology, it is now possible to print objects with multiple materials in a single print job.

This has led to the creation of complex, multi-functional objects with varying properties, such as flexible components embedded within rigid structures.

4. Large-Scale Printing

Traditionally, 3D printers were limited in terms of the size of objects they could produce. However, recent innovations have led to the development of large-scale 3D printers capable of printing objects of significant size.

This has opened up new possibilities in various industries, including construction, aerospace, and automotive.

Large-scale 3D printing enables the production of structures and components that were previously unachievable using conventional manufacturing methods.

5. Integration of 3D Printing with Other Technologies

3D printing technology has also witnessed advancements through its integration with other technologies.

For example, the combination of 3D printing with artificial intelligence and robotics has resulted in the development of autonomous 3D printers that can optimize the printing process and adapt to changing conditions.

Furthermore, the integration of 3D printing with scanning technologies allows for the creation of highly accurate and detailed 3D models, facilitating reverse engineering and customization.

6. Accessibility and Affordability

As 3D printing technology continues to advance, it is becoming more accessible and affordable.

The cost of 3D printers has significantly reduced, making them more accessible to individuals, small businesses, and educational institutions.

Additionally, the availability of open-source software and online platforms has made it easier for people to access and share 3D models, fostering a collaborative and innovative ecosystem.

The advancements and innovations in 3D printing technology have transformed the manufacturing landscape.

From improved printing materials to faster and more precise printing, the possibilities offered by 3D printing are expanding rapidly.

As the technology continues to evolve, it holds the potential to revolutionize industries, drive innovation, and empower individuals to bring their ideas to life.

III. Applications and Impact of 3D Printing in Various Industries

1. Healthcare Industry

3D printing has revolutionized the healthcare industry, enabling the creation of customized medical devices and prosthetics.

This technology has made it possible to produce patient-specific implants, such as dental crowns and orthopedic implants, resulting in better patient outcomes and reduced recovery times.

Additionally, 3D printing has been used to create anatomical models for surgical planning, improving the precision and success rates of complex surgeries.

2. Aerospace and Defense

The aerospace and defense sectors have embraced 3D printing to enhance manufacturing processes and reduce costs.

With the ability to create complex geometries and lightweight structures, this technology has been used to produce aircraft components, engine parts, and even entire rockets.

The use of 3D printing in this industry has significantly reduced lead times and allowed for rapid prototyping, enabling faster innovation and iteration in the development of new products.

3. Automotive Industry

3D printing has disrupted the automotive industry by enabling the production of highly customized and lightweight parts.

This technology has been used to create prototypes, tooling, and even end-use parts, reducing the time and cost traditionally associated with manufacturing.

Moreover, 3D printing has facilitated the design and production of complex and intricate components, improving overall vehicle performance and fuel efficiency.

4. Architecture and Construction

In the field of architecture and construction, 3D printing has opened up new possibilities for design and construction processes.

This technology has been used to create intricate architectural models, allowing architects and designers to visualize and refine their ideas before construction begins.

Additionally, 3D printing has been utilized to fabricate building components, such as walls and facades, reducing construction time and waste while enabling greater design flexibility.

5. Consumer Products

3D printing has also made its way into the consumer products industry, allowing for the creation of personalized and on-demand products.

With the ability to produce small batches or even individual items cost-effectively, this technology has enabled businesses to offer customized products to their customers.

From jewelry and fashion accessories to home decor and electronics, 3D printing has transformed the way consumer products are designed and manufactured.

6. Education and Research

3D printing has become an invaluable tool in education and research, providing hands-on learning experiences and facilitating scientific advancements.

In classrooms, students can design and print their own objects, fostering creativity and problem-solving skills.

In research laboratories, 3D printing has been used to create prototypes, models, and experimental setups, enabling scientists to test and validate their hypotheses more efficiently.

7. Environmental Sustainability

One of the lesser-known but significant impacts of 3D printing is its potential for environmental sustainability.

By enabling local manufacturing and reducing transportation needs, this technology can help minimize carbon emissions associated with traditional supply chains.

Additionally, 3D printing allows for the use of eco-friendly materials and can reduce material waste through optimized designs and production processes.

8. Impact on Supply Chains

The widespread adoption of 3D printing has the potential to disrupt traditional supply chains.

With the ability to produce goods on-site or even at home, this technology could reduce the reliance on centralized manufacturing and global transportation.

This shift could lead to shorter supply chains, reduced inventory levels, and increased customization, ultimately transforming the way products are produced, distributed, and consumed.

9. Social and Ethical Implications

As with any disruptive technology, 3D printing raises social and ethical concerns. The ability to replicate objects and potentially infringe on intellectual property rights has sparked debates on copyright infringement and counterfeiting.

Additionally, the accessibility of 3D printing technology may exacerbate existing inequalities, as those with limited access to resources or knowledge may be left behind in the era of digital manufacturing.

| Industry | Applications |

|---|---|

| Healthcare | Customized medical devices, surgical planning models |

| Aerospace and Defense | Complex aircraft components, rapid prototyping |

| Automotive | Customized and lightweight parts, rapid iteration |

| Architecture and Construction | Architectural models, building components |

| Consumer Products | Personalized and on-demand products |

| Education and Research | Hands-on learning, prototyping |

| Environmental Sustainability | Local manufacturing, eco-friendly materials |

| Supply Chains | Shorter supply chains, reduced inventory levels |

| Social and Ethical Implications | Intellectual property, accessibility |

IV. Future Prospects and Challenges in 3D Printing

1. Advancements in Materials and Printing Techniques

The future of 3D printing holds immense potential for advancements in materials and printing techniques.

As researchers and engineers continue to explore new possibilities, we can expect to see the development of high-performance materials that are specifically tailored for 3D printing applications.

These materials may include advanced alloys, biocompatible polymers, and even conductive or flexible materials.

In addition to materials, there will also be significant advancements in printing techniques. Currently, most 3D printers use layer-by-layer deposition to create objects.

However, future printers may employ multi-material printing or even multi-axis printing, allowing for more complex and intricate designs.

2. Expansion of 3D Printing Applications

While 3D printing has already made a significant impact in various industries, its potential applications are far from being fully realized.

In the future, we can expect to see 3D printing being used in customized healthcare solutions such as patient-specific implants and prosthetics.

The ability to create personalized medical devices will revolutionize the healthcare industry, improving patient outcomes and reducing costs.

Furthermore, 3D printing is likely to play a crucial role in sustainable manufacturing.

By enabling on-demand production and reducing waste, it has the potential to reshape traditional manufacturing processes and reduce the environmental impact of mass production.

3. Challenges to Overcome

Despite the promising future of 3D printing, there are still several challenges that need to be addressed. One of the main challenges is the cost associated with 3D printing technology.

While the prices of 3D printers have significantly decreased over the years, the cost of materials and maintenance can still be prohibitive for many businesses and individuals.

Another challenge is the speed of 3D printing. Although the technology has improved, the process of printing complex objects can still be time-consuming.

Researchers and engineers are actively working on developing faster printing techniques to overcome this limitation.

Additionally, there are regulatory and ethical considerations that need to be addressed.

As 3D printing becomes more prevalent in industries such as healthcare, there will be a need for clear guidelines and regulations to ensure the safety and efficacy of printed products.

| Prospects | Challenges |

|---|---|

|

|

Frequently Asked Questions about the Revolutionary History of 3D Printing

1. What is 3D printing?

3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects by layering materials based on a digital model.

2. When was 3D printing invented?

3D printing was invented in the early 1980s by Chuck Hull, who introduced the first working 3D printer and patented the technology known as stereolithography.

3. How does 3D printing work?

3D printing works by slicing a digital model into thin layers and then printing these layers one on top of the other using various materials, such as plastic, metal, or even living cells.

4. What are the applications of 3D printing?

3D printing has a wide range of applications across various industries, including manufacturing, healthcare, aerospace, automotive, architecture, and even fashion.

5. What are the advantages of 3D printing?

Some advantages of 3D printing include the ability to create complex geometries, reduce waste in production, customize products, and enable rapid prototyping.

6. What are the limitations of 3D printing?

Limitations of 3D printing include high costs of equipment and materials, limited speed of printing, restricted size of objects, and the need for skilled operators.

7. How has 3D printing revolutionized manufacturing?

3D printing has revolutionized manufacturing by enabling decentralized production, reducing supply chain complexity, and allowing on-demand manufacturing of spare parts.

8. Can 3D printing be used in the medical field?

Yes, 3D printing has numerous applications in the medical field, including the production of customized prosthetics, surgical guides, dental implants, and even human organs.

9. What are some notable achievements in 3D printing?

Some notable achievements in 3D printing include the construction of houses using 3D-printed concrete, the printing of functional human organs, and the creation of intricate artistic designs.

10. What does the future hold for 3D printing?

The future of 3D printing looks promising, with advancements in materials, speed, and affordability. It is expected to revolutionize various industries and lead to new possibilities in manufacturing and design.

Wrapping Up

Witness the transformative journey of 3D printing, reshaping industries. Embrace the future of manufacturing with this game-changing technology.

From prototypes to personalized products, its impact is profound.

Stay ahead by exploring the endless possibilities of 3D printing. Revolutionize your approach to creation and innovation.

Dive into the future of crafting, where 3D printing pioneers a new era of limitless potential and groundbreaking possibilities.